PDF Publication Title:

Text from PDF Page: 046

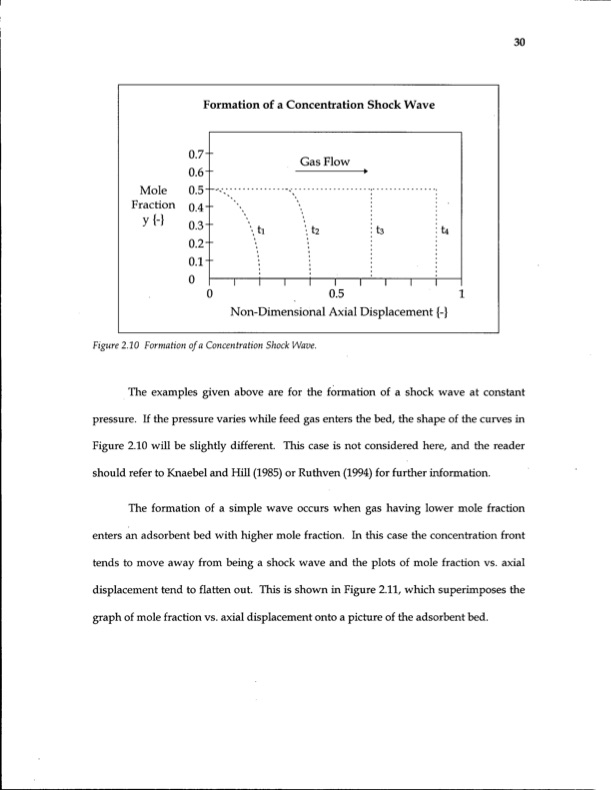

Formation of a Concentration Shock W ave 0.7- 0.6- Mole 0.5- Fraction yH Figure2.10FormationofaConcentrationShockWave. The examples given above are for the formation of a shock wave at constant pressure. If the pressure varies while feed gas enters the bed, the shape of the curves in Figure 2.10 will be slightly different. This case is not considered here, and the reader should refer to Knaebel and Flill (1985) or Ruthven (1994) for further information. The formation of a simple wave occurs when gas having lower mole fraction enters an adsorbent bed with higher mole fraction. In this case the concentration front tends to move away from being a shock wave and the plots of mole fraction vs. axial displacement tend to flatten out. This is shown in Figure 2.11, which superimposes the graph of mole fraction vs. axial displacement onto a picture of the adsorbent bed. 0.4- 0.3- 0.2- o.i- 0 Gas Flow ', t2 t3 ~i 1 1 r 0.5 Non-Dimensional Axial Displacement {-} 30PDF Image | Energy Efficiency of Gas Separation Pressure Swing Adsorption

PDF Search Title:

Energy Efficiency of Gas Separation Pressure Swing AdsorptionOriginal File Name Searched:

ubc_1997-0009.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |