PDF Publication Title:

Text from PDF Page: 073

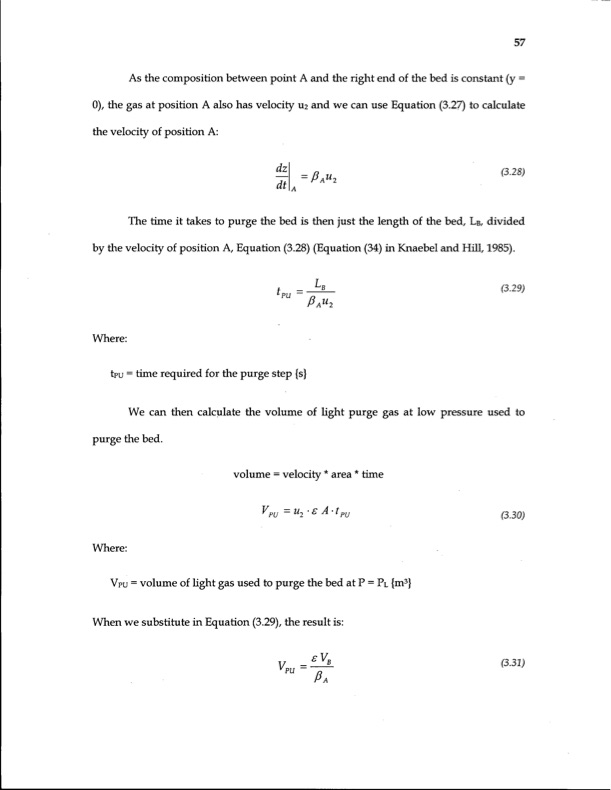

As the composition between point A and the right end of the bed is constant (y = 0), the gas at position A also has velocity ui and we can use Equation (3.27) to calculate the velocity of position A: dz dt A (3.28) The time it takes to purge the bed is then just the length of the bed, LB, divided by the velocity of position A, Equation (3.28) (Equation (34) in Knaebel and Hill, 1985). f - LB (3.29) PA^I Where: tpu = time required for the purge step {s} We can then calculate the volume of light purge gas at low pressure used to purge the bed. volume = velocity * area * time V PU -u2-s A-tPU Where: Vpu = volume of light gas used to purge the bed at P = PL{m3} When we substitute in Equation (3.29), the result is: V = PU £j_30j PA (3-31> 57PDF Image | Energy Efficiency of Gas Separation Pressure Swing Adsorption

PDF Search Title:

Energy Efficiency of Gas Separation Pressure Swing AdsorptionOriginal File Name Searched:

ubc_1997-0009.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |