PDF Publication Title:

Text from PDF Page: 015

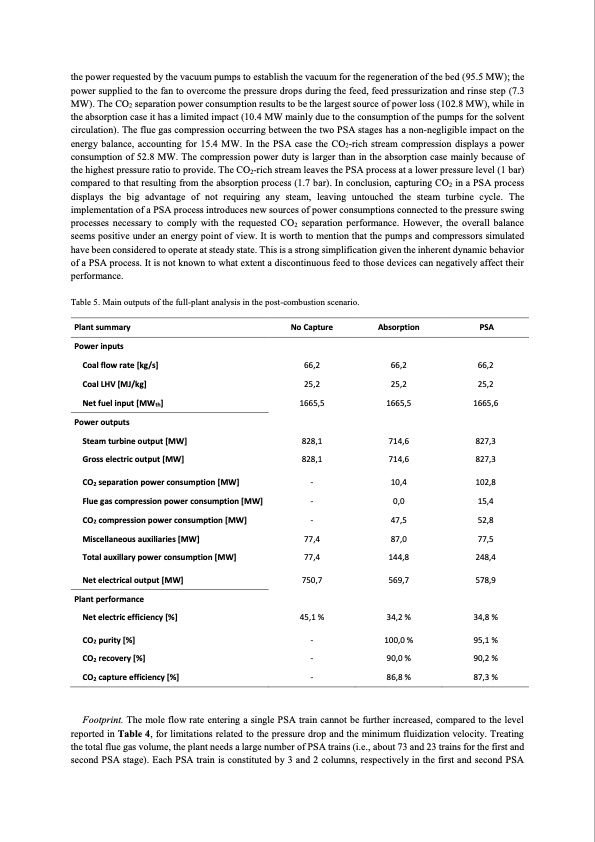

the power requested by the vacuum pumps to establish the vacuum for the regeneration of the bed (95.5 MW); the power supplied to the fan to overcome the pressure drops during the feed, feed pressurization and rinse step (7.3 MW). The CO2 separation power consumption results to be the largest source of power loss (102.8 MW), while in the absorption case it has a limited impact (10.4 MW mainly due to the consumption of the pumps for the solvent circulation). The flue gas compression occurring between the two PSA stages has a non-negligible impact on the energy balance, accounting for 15.4 MW. In the PSA case the CO2-rich stream compression displays a power consumption of 52.8 MW. The compression power duty is larger than in the absorption case mainly because of the highest pressure ratio to provide. The CO2-rich stream leaves the PSA process at a lower pressure level (1 bar) compared to that resulting from the absorption process (1.7 bar). In conclusion, capturing CO2 in a PSA process displays the big advantage of not requiring any steam, leaving untouched the steam turbine cycle. The implementation of a PSA process introduces new sources of power consumptions connected to the pressure swing processes necessary to comply with the requested CO2 separation performance. However, the overall balance seems positive under an energy point of view. It is worth to mention that the pumps and compressors simulated have been considered to operate at steady state. This is a strong simplification given the inherent dynamic behavior of a PSA process. It is not known to what extent a discontinuous feed to those devices can negatively affect their performance. Table 5. Main outputs of the full-plant analysis in the post-combustion scenario. Plant summary Power inputs Coal flow rate [kg/s] Coal LHV [MJ/kg] Net fuel input [MWth] Power outputs Steam turbine output [MW] Gross electric output [MW] CO2 separation power consumption [MW] Flue gas compression power consumption [MW] CO2 compression power consumption [MW] Miscellaneous auxiliaries [MW] Total auxillary power consumption [MW] Net electrical output [MW] Plant performance Net electric efficiency [%] CO2 purity [%] CO2 recovery [%] CO2 capture efficiency [%] No Capture 66,2 25,2 1665,5 828,1 828,1 - - - 77,4 77,4 750,7 45,1 % - - - Absorption 66,2 25,2 1665,5 714,6 714,6 10,4 0,0 47,5 87,0 144,8 569,7 34,2 % 100,0 % 90,0 % 86,8 % PSA 66,2 25,2 1665,6 827,3 827,3 102,8 15,4 52,8 77,5 248,4 578,9 34,8 % 95,1 % 90,2 % 87,3 % Footprint. The mole flow rate entering a single PSA train cannot be further increased, compared to the level reported in Table 4, for limitations related to the pressure drop and the minimum fluidization velocity. Treating the total flue gas volume, the plant needs a large number of PSA trains (i.e., about 73 and 23 trains for the first and second PSA stage). Each PSA train is constituted by 3 and 2 columns, respectively in the first and second PSAPDF Image | Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-fired

PDF Search Title:

Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-firedOriginal File Name Searched:

PSA-coal-fired-plants.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |