PDF Publication Title:

Text from PDF Page: 014

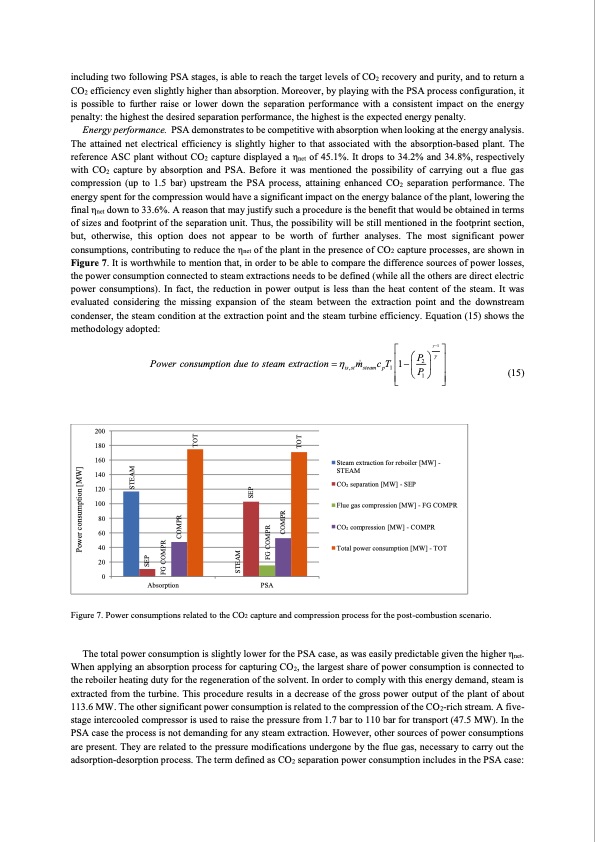

including two following PSA stages, is able to reach the target levels of CO2 recovery and purity, and to return a CO2 efficiency even slightly higher than absorption. Moreover, by playing with the PSA process configuration, it is possible to further raise or lower down the separation performance with a consistent impact on the energy penalty: the highest the desired separation performance, the highest is the expected energy penalty. Energy performance. PSA demonstrates to be competitive with absorption when looking at the energy analysis. The attained net electrical efficiency is slightly higher to that associated with the absorption-based plant. The reference ASC plant without CO2 capture displayed a ηnet of 45.1%. It drops to 34.2% and 34.8%, respectively with CO2 capture by absorption and PSA. Before it was mentioned the possibility of carrying out a flue gas compression (up to 1.5 bar) upstream the PSA process, attaining enhanced CO2 separation performance. The energy spent for the compression would have a significant impact on the energy balance of the plant, lowering the final ηnet down to 33.6%. A reason that may justify such a procedure is the benefit that would be obtained in terms of sizes and footprint of the separation unit. Thus, the possibility will be still mentioned in the footprint section, but, otherwise, this option does not appear to be worth of further analyses. The most significant power consumptions, contributing to reduce the ηnet of the plant in the presence of CO2 capture processes, are shown in Figure 7. It is worthwhile to mention that, in order to be able to compare the difference sources of power losses, the power consumption connected to steam extractions needs to be defined (while all the others are direct electric power consumptions). In fact, the reduction in power output is less than the heat content of the steam. It was evaluated considering the missing expansion of the steam between the extraction point and the downstream condenser, the steam condition at the extraction point and the steam turbine efficiency. Equation (15) shows the methodology adopted: 1 Power consumption due to steam extraction m c T 1 P is,st steamp12 P (15) 1 200 180 160 140 120 100 80 60 40 20 0 Steam extraction for reboiler [MW] - STEAM CO2 separation [MW] - SEP Flue gas compression [MW] - FG COMPR CO2 compression [MW] - COMPR Total power consumption [MW] - TOT Absorption PSA Figure 7. Power consumptions related to the CO2 capture and compression process for the post-combustion scenario. The total power consumption is slightly lower for the PSA case, as was easily predictable given the higher ηnet. When applying an absorption process for capturing CO2, the largest share of power consumption is connected to the reboiler heating duty for the regeneration of the solvent. In order to comply with this energy demand, steam is extracted from the turbine. This procedure results in a decrease of the gross power output of the plant of about 113.6 MW. The other significant power consumption is related to the compression of the CO2-rich stream. A five- stage intercooled compressor is used to raise the pressure from 1.7 bar to 110 bar for transport (47.5 MW). In the PSA case the process is not demanding for any steam extraction. However, other sources of power consumptions are present. They are related to the pressure modifications undergone by the flue gas, necessary to carry out the adsorption-desorption process. The term defined as CO2 separation power consumption includes in the PSA case: SEP FG COMPR STEAM Power consumption [MW] COMPR FG COMPR COMPR SEP STEAM TOT TOTPDF Image | Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-fired

PDF Search Title:

Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-firedOriginal File Name Searched:

PSA-coal-fired-plants.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |