PDF Publication Title:

Text from PDF Page: 017

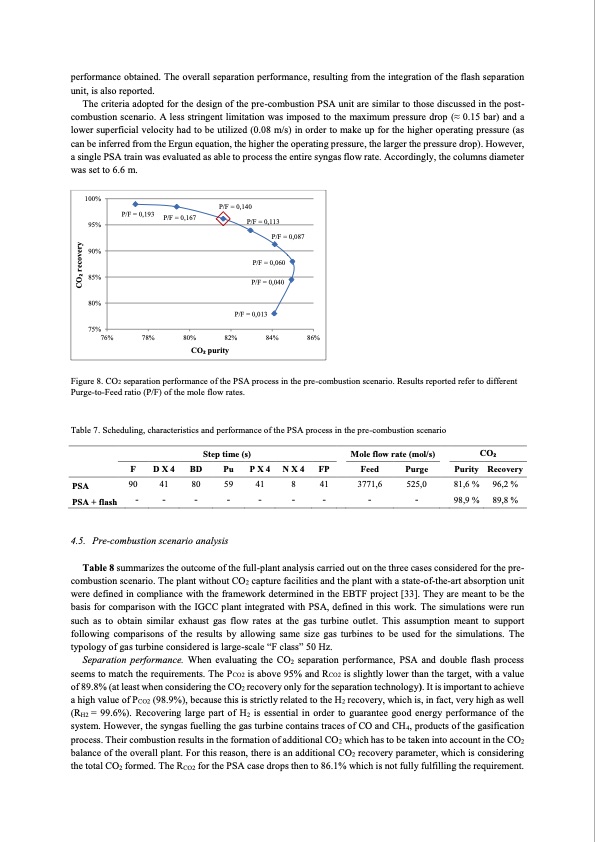

performance obtained. The overall separation performance, resulting from the integration of the flash separation unit, is also reported. The criteria adopted for the design of the pre-combustion PSA unit are similar to those discussed in the post- combustion scenario. A less stringent limitation was imposed to the maximum pressure drop (≈ 0.15 bar) and a lower superficial velocity had to be utilized (0.08 m/s) in order to make up for the higher operating pressure (as can be inferred from the Ergun equation, the higher the operating pressure, the larger the pressure drop). However, a single PSA train was evaluated as able to process the entire syngas flow rate. Accordingly, the columns diameter was set to 6.6 m. 100% 95% 90% 85% 80% P/F = 0,193 P/F = 0,167 80% P/F = 0,140 P/F = 0,113 P/F = 0,087 P/F = 0,060 P/F = 0,040 P/F = 0,013 82% 84% 86% 75% 76% 78% CO2 purity Figure 8. CO2 separation performance of the PSA process in the pre-combustion scenario. Results reported refer to different Purge-to-Feed ratio (P/F) of the mole flow rates. Table 7. Scheduling, characteristics and performance of the PSA process in the pre-combustion scenario CO2 Recovery Table 8 summarizes the outcome of the full-plant analysis carried out on the three cases considered for the pre- combustion scenario. The plant without CO2 capture facilities and the plant with a state-of-the-art absorption unit were defined in compliance with the framework determined in the EBTF project [33]. They are meant to be the basis for comparison with the IGCC plant integrated with PSA, defined in this work. The simulations were run such as to obtain similar exhaust gas flow rates at the gas turbine outlet. This assumption meant to support following comparisons of the results by allowing same size gas turbines to be used for the simulations. The typology of gas turbine considered is large-scale “F class” 50 Hz. Separation performance. When evaluating the CO2 separation performance, PSA and double flash process seems to match the requirements. The PCO2 is above 95% and RCO2 is slightly lower than the target, with a value of 89.8% (at least when considering the CO2 recovery only for the separation technology). It is important to achieve a high value of PCO2 (98.9%), because this is strictly related to the H2 recovery, which is, in fact, very high as well (RH2 = 99.6%). Recovering large part of H2 is essential in order to guarantee good energy performance of the system. However, the syngas fuelling the gas turbine contains traces of CO and CH4, products of the gasification process. Their combustion results in the formation of additional CO2 which has to be taken into account in the CO2 balance of the overall plant. For this reason, there is an additional CO2 recovery parameter, which is considering the total CO2 formed. The RCO2 for the PSA case drops then to 86.1% which is not fully fulfilling the requirement. Step time (s) F D X 4 BD Pu P X 4 90 41 80 59 41 N X 4 FP 8 41 Mole flow rate (mol/s) Feed Purge 3771,6 525,0 Purity PSA PSA + flash 96,2 % - - - - - - - 81,6 % - - 98,9% 89,8% 4.5. Pre-combustion scenario analysis CO2 recoveryPDF Image | Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-fired

PDF Search Title:

Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-firedOriginal File Name Searched:

PSA-coal-fired-plants.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |