PDF Publication Title:

Text from PDF Page: 018

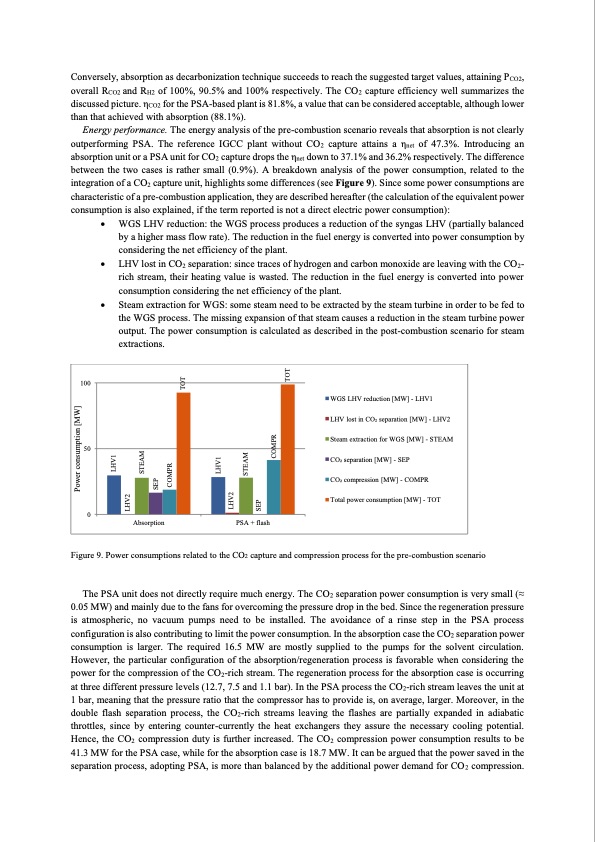

Conversely, absorption as decarbonization technique succeeds to reach the suggested target values, attaining PCO2, overall RCO2 and RH2 of 100%, 90.5% and 100% respectively. The CO2 capture efficiency well summarizes the discussed picture. ηCO2 for the PSA-based plant is 81.8%, a value that can be considered acceptable, although lower than that achieved with absorption (88.1%). Energy performance. The energy analysis of the pre-combustion scenario reveals that absorption is not clearly outperforming PSA. The reference IGCC plant without CO2 capture attains a ηnet of 47.3%. Introducing an absorption unit or a PSA unit for CO2 capture drops the ηnet down to 37.1% and 36.2% respectively. The difference between the two cases is rather small (0.9%). A breakdown analysis of the power consumption, related to the integration of a CO2 capture unit, highlights some differences (see Figure 9). Since some power consumptions are characteristic of a pre-combustion application, they are described hereafter (the calculation of the equivalent power consumption is also explained, if the term reported is not a direct electric power consumption): WGS LHV reduction: the WGS process produces a reduction of the syngas LHV (partially balanced by a higher mass flow rate). The reduction in the fuel energy is converted into power consumption by considering the net efficiency of the plant. LHV lost in CO2 separation: since traces of hydrogen and carbon monoxide are leaving with the CO2- rich stream, their heating value is wasted. The reduction in the fuel energy is converted into power consumption considering the net efficiency of the plant. Steam extraction for WGS: some steam need to be extracted by the steam turbine in order to be fed to the WGS process. The missing expansion of that steam causes a reduction in the steam turbine power output. The power consumption is calculated as described in the post-combustion scenario for steam extractions. 100 50 0 WGS LHV reduction [MW] - LHV1 LHV lost in CO2 separation [MW] - LHV2 Steam extraction for WGS [MW] - STEAM CO2 separation [MW] - SEP CO2 compression [MW] - COMPR Total power consumption [MW] - TOT Absorption PSA + flash Figure 9. Power consumptions related to the CO2 capture and compression process for the pre-combustion scenario The PSA unit does not directly require much energy. The CO2 separation power consumption is very small (≈ 0.05 MW) and mainly due to the fans for overcoming the pressure drop in the bed. Since the regeneration pressure is atmospheric, no vacuum pumps need to be installed. The avoidance of a rinse step in the PSA process configuration is also contributing to limit the power consumption. In the absorption case the CO2 separation power consumption is larger. The required 16.5 MW are mostly supplied to the pumps for the solvent circulation. However, the particular configuration of the absorption/regeneration process is favorable when considering the power for the compression of the CO2-rich stream. The regeneration process for the absorption case is occurring at three different pressure levels (12.7, 7.5 and 1.1 bar). In the PSA process the CO2-rich stream leaves the unit at 1 bar, meaning that the pressure ratio that the compressor has to provide is, on average, larger. Moreover, in the double flash separation process, the CO2-rich streams leaving the flashes are partially expanded in adiabatic throttles, since by entering counter-currently the heat exchangers they assure the necessary cooling potential. Hence, the CO2 compression duty is further increased. The CO2 compression power consumption results to be 41.3 MW for the PSA case, while for the absorption case is 18.7 MW. It can be argued that the power saved in the separation process, adopting PSA, is more than balanced by the additional power demand for CO2 compression. Power consumption [MW] LHV1 LHV2 STEAM SEP COMPR LHV1 LHV2 STEAM SEP COMPR TOT TOTPDF Image | Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-fired

PDF Search Title:

Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-firedOriginal File Name Searched:

PSA-coal-fired-plants.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |