PDF Publication Title:

Text from PDF Page: 028

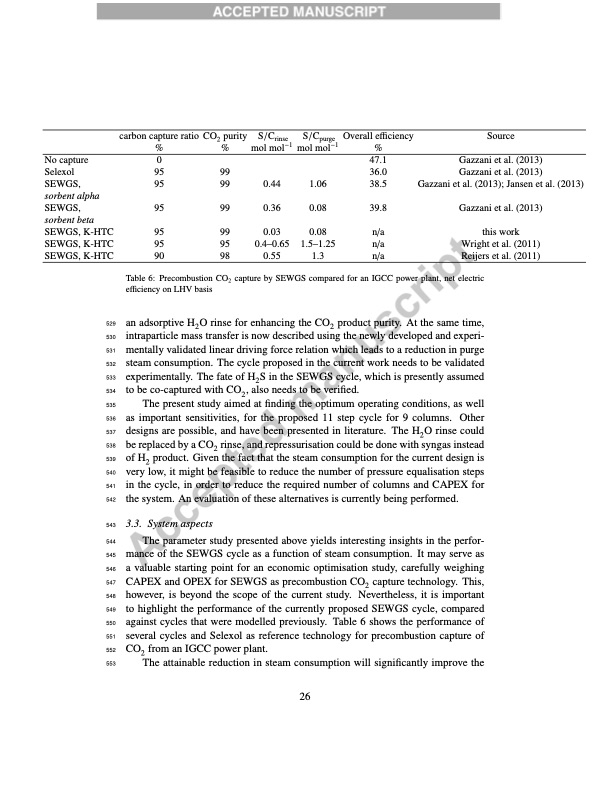

carbon capture ratio CO2 purity % % S/Crinse S/Cpurge molmol−1 molmol−1 Overall efficiency % 47.1 36.0 38.5 39.8 n/a n/a n/a Source Gazzani et al. (2013) Gazzani et al. (2013) Gazzani et al. (2013); Jansen et al. (2013) Gazzani et al. (2013) this work Wright et al. (2011) Reijers et al. (2011) No capture 0 Selexol 95 99 SEWGS, 95 99 0.44 sorbent alpha SEWGS, 95 99 0.36 sorbent beta SEWGS, K-HTC 95 99 0.03 SEWGS, K-HTC 95 95 0.4–0.65 SEWGS, K-HTC 90 98 0.55 1.06 0.08 0.08 1.5–1.25 1.3 529 530 531 532 533 534 535 536 537 538 539 540 541 542 543 544 545 546 547 548 549 550 551 552 553 Table 6: Precombustion CO2 capture by SEWGS compared for an IGCC power plant, net electric efficiency on LHV basis an adsorptive H2O rinse for enhancing the CO2 product purity. At the same time, intraparticle mass transfer is now described using the newly developed and experi- mentally validated linear driving force relation which leads to a reduction in purge steam consumption. The cycle proposed in the current work needs to be validated experimentally. The fate of H2S in the SEWGS cycle, which is presently assumed to be co-captured with CO2, also needs to be verified. The present study aimed at finding the optimum operating conditions, as well as important sensitivities, for the proposed 11 step cycle for 9 columns. Other designs are possible, and have been presented in literature. The H2O rinse could be replaced by a CO2 rinse, and repressurisation could be done with syngas instead of H2 product. Given the fact that the steam consumption for the current design is very low, it might be feasible to reduce the number of pressure equalisation steps in the cycle, in order to reduce the required number of columns and CAPEX for the system. An evaluation of these alternatives is currently being performed. 3.3. System aspects The parameter study presented above yields interesting insights in the perfor- mance of the SEWGS cycle as a function of steam consumption. It may serve as a valuable starting point for an economic optimisation study, carefully weighing CAPEX and OPEX for SEWGS as precombustion CO2 capture technology. This, however, is beyond the scope of the current study. Nevertheless, it is important to highlight the performance of the currently proposed SEWGS cycle, compared against cycles that were modelled previously. Table 6 shows the performance of several cycles and Selexol as reference technology for precombustion capture of CO2 from an IGCC power plant. The attainable reduction in steam consumption will significantly improve the 26PDF Image | High-temperature pressure swing adsorption cycle design for sorption

PDF Search Title:

High-temperature pressure swing adsorption cycle design for sorptionOriginal File Name Searched:

high-temperature-pressure-swing-adsorption.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |