PDF Publication Title:

Text from PDF Page: 108

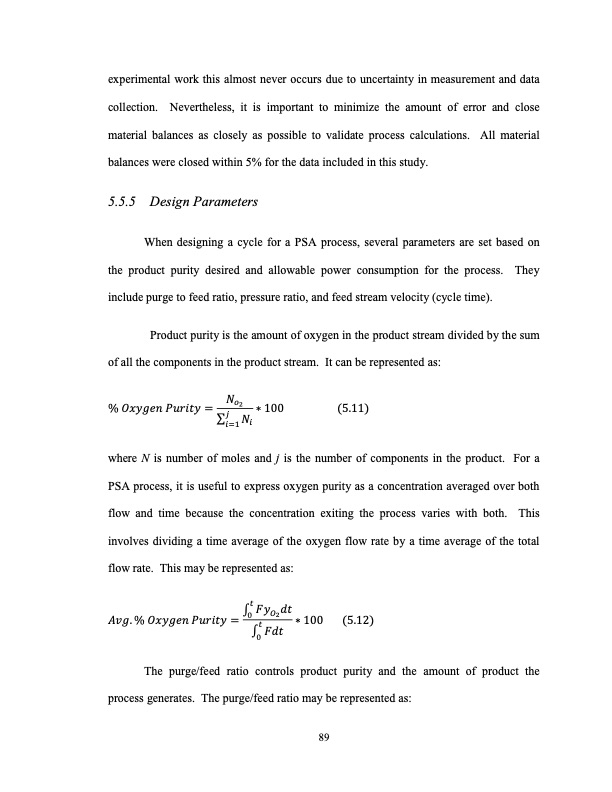

experimental work this almost never occurs due to uncertainty in measurement and data collection. Nevertheless, it is important to minimize the amount of error and close material balances as closely as possible to validate process calculations. All material balances were closed within 5% for the data included in this study. 5.5.5 Design Parameters When designing a cycle for a PSA process, several parameters are set based on the product purity desired and allowable power consumption for the process. They include purge to feed ratio, pressure ratio, and feed stream velocity (cycle time). Product purity is the amount of oxygen in the product stream divided by the sum of all the components in the product stream. It can be represented as: where N is number of moles and j is the number of components in the product. For a PSA process, it is useful to express oxygen purity as a concentration averaged over both flow and time because the concentration exiting the process varies with both. This involves dividing a time average of the oxygen flow rate by a time average of the total flow rate. This may be represented as: The purge/feed ratio controls product purity and the amount of product the process generates. The purge/feed ratio may be represented as: 89PDF Image | LIMITS OF SMALL SCALE PRESSURE SWING ADSORPTION

PDF Search Title:

LIMITS OF SMALL SCALE PRESSURE SWING ADSORPTIONOriginal File Name Searched:

Limits of Small Scale PSA_Aaron Moran.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |