PDF Publication Title:

Text from PDF Page: 044

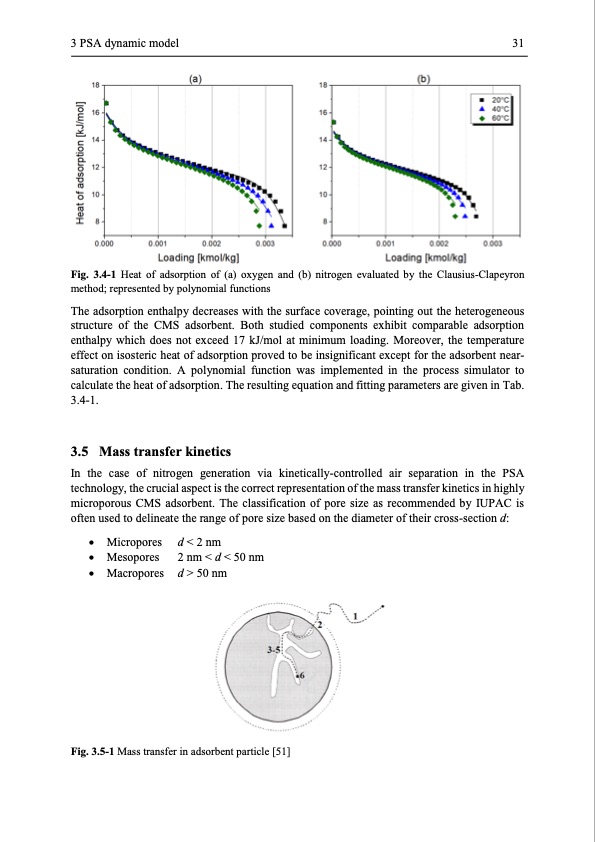

3 PSA dynamic model 31 Fig. 3.4-1 Heat of adsorption of (a) oxygen and (b) nitrogen evaluated by the Clausius-Clapeyron method; represented by polynomial functions 3.4-1. 3.5 Mass transfer kinetics In the case of nitrogen generation via kinetically-controlled air separation in the PSA technology, the crucial aspect is the correct representation of the mass transfer kinetics in highly microporous CMS adsorbent. The classification of pore size as recommended by IUPAC is often used to delineate the range of pore size based on the diameter of their cross-section d: The adsorption enthalpy decreases with the surface coverage, pointing out the heterogeneous structure of the CMS adsorbent. Both studied components exhibit comparable adsorption enthalpy which does not exceed 17 kJ/mol at minimum loading. Moreover, the temperature effect on isosteric heat of adsorption proved to be insignificant except for the adsorbent near- saturation condition. A polynomial function was implemented in the process simulator to calculate the heat of adsorption. The resulting equation and fitting parameters are given in Tab. • Micropores • Mesopores • Macropores d < 2 nm 2 nm < d < 50 nm d > 50 nm Fig. 3.5-1 Mass transfer in adsorbent particle [51]PDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |