PDF Publication Title:

Text from PDF Page: 045

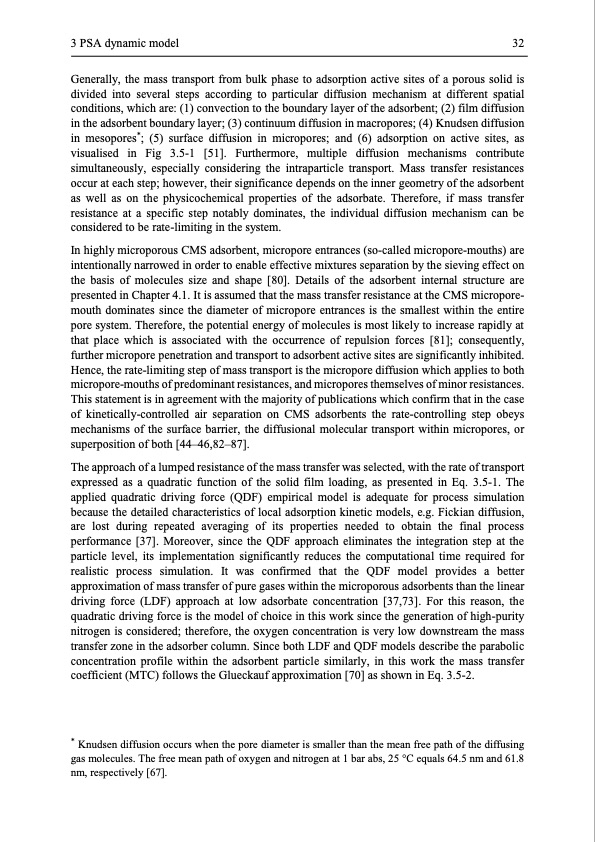

3 PSA dynamic model 32 Generally, the mass transport from bulk phase to adsorption active sites of a porous solid is divided into several steps according to particular diffusion mechanism at different spatial conditions, which are: (1) convection to the boundary layer of the adsorbent; (2) film diffusion in the adsorbent boundary layer; (3) continuum diffusion in macropores; (4) Knudsen diffusion in mesopores*; (5) surface diffusion in micropores; and (6) adsorption on active sites, as visualised in Fig 3.5-1 [51]. Furthermore, multiple diffusion mechanisms contribute simultaneously, especially considering the intraparticle transport. Mass transfer resistances occur at each step; however, their significance depends on the inner geometry of the adsorbent as well as on the physicochemical properties of the adsorbate. Therefore, if mass transfer resistance at a specific step notably dominates, the individual diffusion mechanism can be considered to be rate-limiting in the system. In highly microporous CMS adsorbent, micropore entrances (so-called micropore-mouths) are intentionally narrowed in order to enable effective mixtures separation by the sieving effect on the basis of molecules size and shape [80]. Details of the adsorbent internal structure are presented in Chapter 4.1. It is assumed that the mass transfer resistance at the CMS micropore- mouth dominates since the diameter of micropore entrances is the smallest within the entire pore system. Therefore, the potential energy of molecules is most likely to increase rapidly at that place which is associated with the occurrence of repulsion forces [81]; consequently, further micropore penetration and transport to adsorbent active sites are significantly inhibited. Hence, the rate-limiting step of mass transport is the micropore diffusion which applies to both micropore-mouths of predominant resistances, and micropores themselves of minor resistances. This statement is in agreement with the majority of publications which confirm that in the case of kinetically-controlled air separation on CMS adsorbents the rate-controlling step obeys mechanisms of the surface barrier, the diffusional molecular transport within micropores, or superposition of both [44–46,82–87]. The approach of a lumped resistance of the mass transfer was selected, with the rate of transport expressed as a quadratic function of the solid film loading, as presented in Eq. 3.5-1. The applied quadratic driving force (QDF) empirical model is adequate for process simulation because the detailed characteristics of local adsorption kinetic models, e.g. Fickian diffusion, are lost during repeated averaging of its properties needed to obtain the final process performance [37]. Moreover, since the QDF approach eliminates the integration step at the particle level, its implementation significantly reduces the computational time required for realistic process simulation. It was confirmed that the QDF model provides a better approximation of mass transfer of pure gases within the microporous adsorbents than the linear driving force (LDF) approach at low adsorbate concentration [37,73]. For this reason, the quadratic driving force is the model of choice in this work since the generation of high-purity nitrogen is considered; therefore, the oxygen concentration is very low downstream the mass transfer zone in the adsorber column. Since both LDF and QDF models describe the parabolic concentration profile within the adsorbent particle similarly, in this work the mass transfer coefficient (MTC) follows the Glueckauf approximation [70] as shown in Eq. 3.5-2. * Knudsen diffusion occurs when the pore diameter is smaller than the mean free path of the diffusing gas molecules. The free mean path of oxygen and nitrogen at 1 bar abs, 25 °C equals 64.5 nm and 61.8 nm, respectively [67].PDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |