PDF Publication Title:

Text from PDF Page: 052

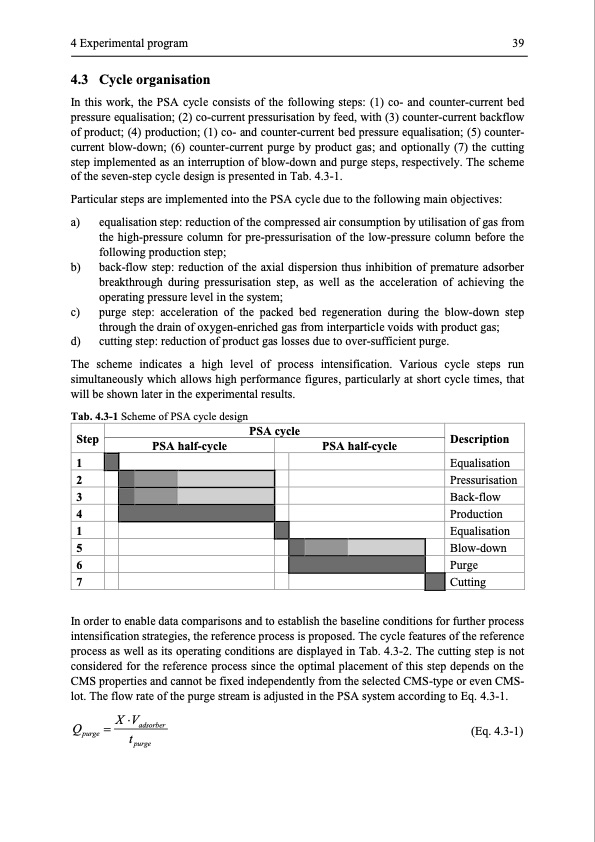

4 Experimental program 39 4.3 Cycle organisation In this work, the PSA cycle consists of the following steps: (1) co- and counter-current bed pressure equalisation; (2) co-current pressurisation by feed, with (3) counter-current backflow of product; (4) production; (1) co- and counter-current bed pressure equalisation; (5) counter- current blow-down; (6) counter-current purge by product gas; and optionally (7) the cutting step implemented as an interruption of blow-down and purge steps, respectively. The scheme of the seven-step cycle design is presented in Tab. 4.3-1. Particular steps are implemented into the PSA cycle due to the following main objectives: a) equalisation step: reduction of the compressed air consumption by utilisation of gas from the high-pressure column for pre-pressurisation of the low-pressure column before the following production step; b) back-flow step: reduction of the axial dispersion thus inhibition of premature adsorber breakthrough during pressurisation step, as well as the acceleration of achieving the operating pressure level in the system; c) purge step: acceleration of the packed bed regeneration during the blow-down step through the drain of oxygen-enriched gas from interparticle voids with product gas; d) cutting step: reduction of product gas losses due to over-sufficient purge. The scheme indicates a high level of process intensification. Various cycle steps run simultaneously which allows high performance figures, particularly at short cycle times, that will be shown later in the experimental results. Tab. 4.3-1 Scheme of PSA cycle design Step 1 2 3 4 1 5 6 7 PSA cycle Description Equalisation Pressurisation Back-flow Production Equalisation Blow-down Purge Cutting PSA half-cycle PSA half-cycle In order to enable data comparisons and to establish the baseline conditions for further process intensification strategies, the reference process is proposed. The cycle features of the reference process as well as its operating conditions are displayed in Tab. 4.3-2. The cutting step is not considered for the reference process since the optimal placement of this step depends on the CMS properties and cannot be fixed independently from the selected CMS-type or even CMS- lot. The flow rate of the purge stream is adjusted in the PSA system according to Eq. 4.3-1. Q = X Vadsorber purge t (Eq. 4.3-1) purgePDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |