PDF Publication Title:

Text from PDF Page: 053

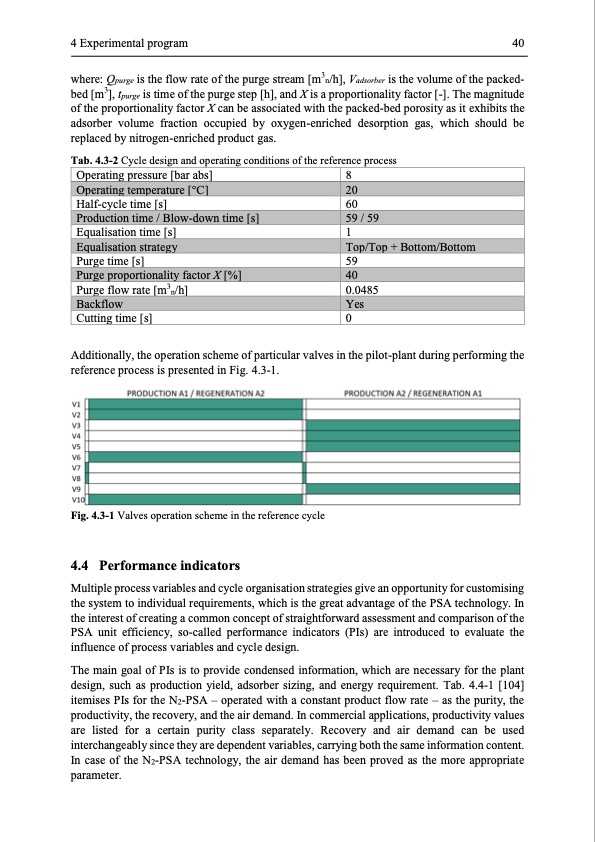

4 Experimental program 40 where: Qpurge is the flow rate of the purge stream [m3n/h], Vadsorber is the volume of the packed- bed [m3], tpurge is time of the purge step [h], and X is a proportionality factor [-]. The magnitude of the proportionality factor X can be associated with the packed-bed porosity as it exhibits the adsorber volume fraction occupied by oxygen-enriched desorption gas, which should be replaced by nitrogen-enriched product gas. Tab. 4.3-2 Cycle design and operating conditions of the reference process Operating pressure [bar abs] 8 Half-cycle time [s] 60 Equalisation time [s] 1 Purge time [s] 59 Purge flow rate [m3n/h] 0.0485 Cutting time [s] 0 Additionally, the operation scheme of particular valves in the pilot-plant during performing the reference process is presented in Fig. 4.3-1. Fig. 4.3-1 Valves operation scheme in the reference cycle 4.4 Performance indicators Multiple process variables and cycle organisation strategies give an opportunity for customising the system to individual requirements, which is the great advantage of the PSA technology. In the interest of creating a common concept of straightforward assessment and comparison of the PSA unit efficiency, so-called performance indicators (PIs) are introduced to evaluate the influence of process variables and cycle design. The main goal of PIs is to provide condensed information, which are necessary for the plant design, such as production yield, adsorber sizing, and energy requirement. Tab. 4.4-1 [104] itemises PIs for the N2-PSA – operated with a constant product flow rate – as the purity, the productivity, the recovery, and the air demand. In commercial applications, productivity values are listed for a certain purity class separately. Recovery and air demand can be used interchangeably since they are dependent variables, carrying both the same information content. In case of the N2-PSA technology, the air demand has been proved as the more appropriate parameter. Operating temperature [°C] 20 Production time / Blow-down time [s] 59 / 59 Equalisation strategy Top/Top + Bottom/Bottom Purge proportionality factor X [%] 40 Backflow YesPDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |