PDF Publication Title:

Text from PDF Page: 054

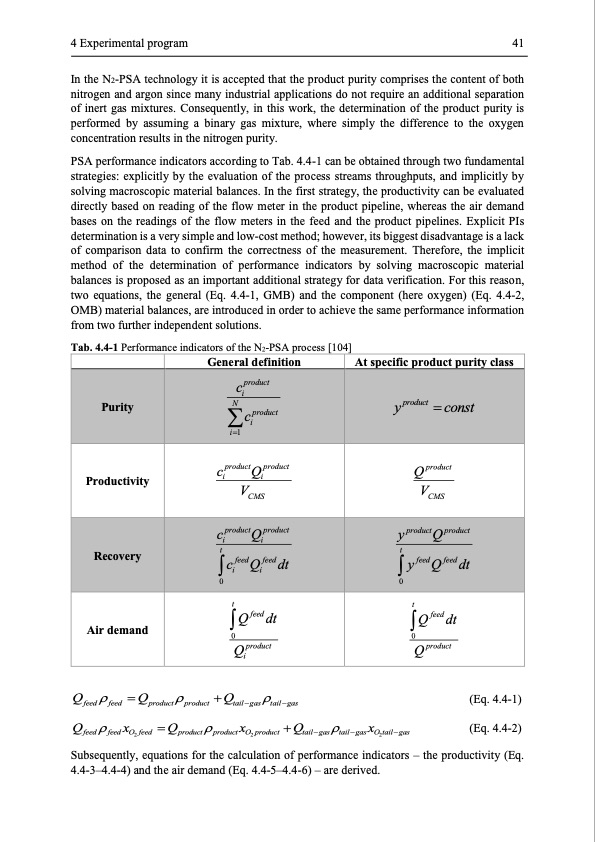

4 Experimental program 41 In the N2-PSA technology it is accepted that the product purity comprises the content of both nitrogen and argon since many industrial applications do not require an additional separation of inert gas mixtures. Consequently, in this work, the determination of the product purity is performed by assuming a binary gas mixture, where simply the difference to the oxygen concentration results in the nitrogen purity. PSA performance indicators according to Tab. 4.4-1 can be obtained through two fundamental strategies: explicitly by the evaluation of the process streams throughputs, and implicitly by solving macroscopic material balances. In the first strategy, the productivity can be evaluated directly based on reading of the flow meter in the product pipeline, whereas the air demand bases on the readings of the flow meters in the feed and the product pipelines. Explicit PIs determination is a very simple and low-cost method; however, its biggest disadvantage is a lack of comparison data to confirm the correctness of the measurement. Therefore, the implicit method of the determination of performance indicators by solving macroscopic material balances is proposed as an important additional strategy for data verification. For this reason, two equations, the general (Eq. 4.4-1, GMB) and the component (here oxygen) (Eq. 4.4-2, OMB) material balances, are introduced in order to achieve the same performance information from two further independent solutions. Tab. 4.4-1 Performance indicators of the N2-PSA process [104] General definition At specific product purity class Purity c product i N product ci i =1 yproduct =const Productivity c product Q product ii VCMS Q product VCMS Recovery c product Q product ii t 0 cfeedQfeeddt ii y product Q product t 0 yfeedQfeeddt Air demand t Qfeeddt 0 Q product i t Qfeeddt 0 Q product Qfeedfeed =Qproductproduct +Qtail−gastail−gas (Eq.4.4-1) QfeedfeedxO2 feed =QproductproductxO2product +Qtail−gastail−gasxO2tail−gas (Eq.4.4-2) Subsequently, equations for the calculation of performance indicators – the productivity (Eq. 4.4-3–4.4-4) and the air demand (Eq. 4.4-5–4.4-6) – are derived.PDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |