PDF Publication Title:

Text from PDF Page: 093

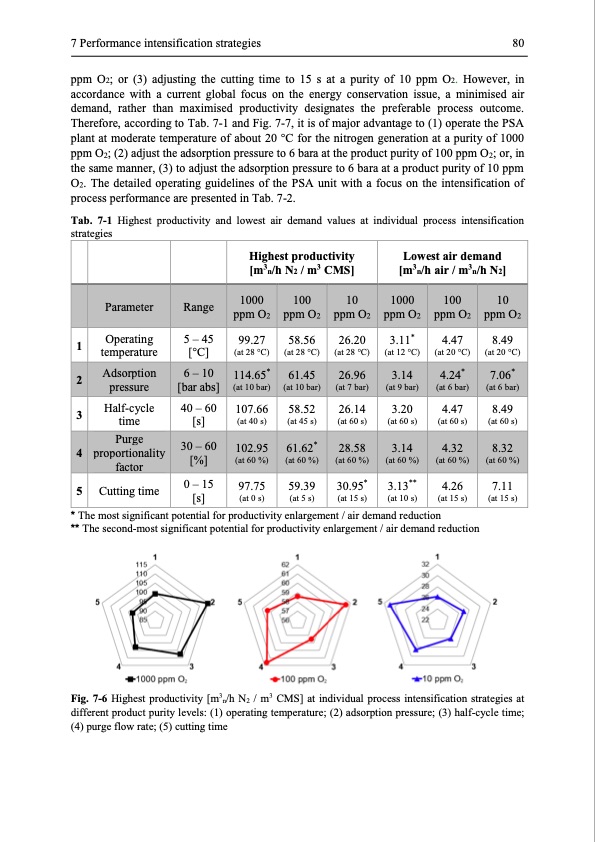

7 Performance intensification strategies 80 ppm O2; or (3) adjusting the cutting time to 15 s at a purity of 10 ppm O2. However, in accordance with a current global focus on the energy conservation issue, a minimised air demand, rather than maximised productivity designates the preferable process outcome. Therefore, according to Tab. 7-1 and Fig. 7-7, it is of major advantage to (1) operate the PSA plant at moderate temperature of about 20 °C for the nitrogen generation at a purity of 1000 ppm O2; (2) adjust the adsorption pressure to 6 bara at the product purity of 100 ppm O2; or, in the same manner, (3) to adjust the adsorption pressure to 6 bara at a product purity of 10 ppm O2. The detailed operating guidelines of the PSA unit with a focus on the intensification of process performance are presented in Tab. 7-2. Tab. 7-1 Highest productivity and lowest air demand values at individual process intensification strategies Highest productivity [m3n/h N2 / m3 CMS] Lowest air demand [m3n/h air / m3n/h N2] Parameter Range 1000 ppm O2 100 ppm O2 10 ppm O2 1000 ppm O2 100 ppm O2 10 ppm O2 1 2 3 4 99.27 (at 28 °C) 107.66 (at 40 s) 58.56 (at 28 °C) 58.52 (at 45 s) 26.20 (at 28 °C) 26.14 (at 60 s) 3.11* (at 12 °C) 3.20 (at 60 s) 4.47 (at 20 °C) 4.47 (at 60 s) 4.26 (at 15 s) 8.49 (at 20 °C) 8.49 (at 60 s) 7.11 (at 15 s) Operating temperature Half-cycle time 5 – 45 [°C] 40 – 60 [s] ** The second-most significant potential for productivity enlargement / air demand reduction Adsorption pressure 6 – 10 [bar abs] 114.65* (at 10 bar) 61.45 (at 10 bar) 26.96 (at 7 bar) 3.14 (at 9 bar) 4.24* (at 6 bar) 7.06* (at 6 bar) Purge proportionality factor 30 – 60 [%] 102.95 (at 60 %) 61.62* (at 60 %) 28.58 (at 60 %) 3.14 (at 60 %) 4.32 (at 60 %) 8.32 (at 60 %) 0 – 15 [s] 97.75 (at 0 s) 59.39 (at 5 s) 30.95* (at 15 s) 3.13** (at 10 s) 5 Cutting time * The most significant potential for productivity enlargement / air demand reduction Fig. 7-6 Highest productivity [m3n/h N2 / m3 CMS] at individual process intensification strategies at different product purity levels: (1) operating temperature; (2) adsorption pressure; (3) half-cycle time; (4) purge flow rate; (5) cutting timePDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |