PDF Publication Title:

Text from PDF Page: 094

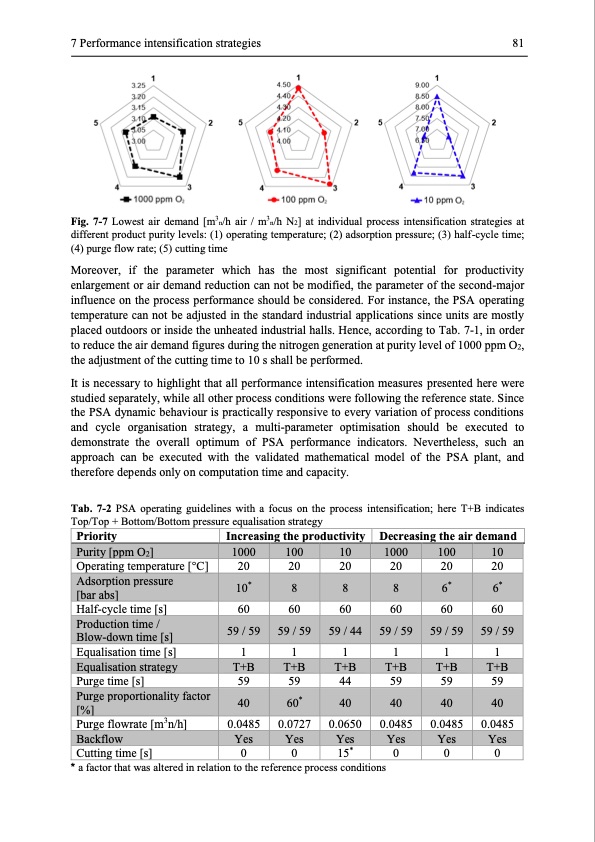

7 Performance intensification strategies 81 Fig. 7-7 Lowest air demand [m3n/h air / m3n/h N2] at individual process intensification strategies at different product purity levels: (1) operating temperature; (2) adsorption pressure; (3) half-cycle time; (4) purge flow rate; (5) cutting time Moreover, if the parameter which has the most significant potential for productivity enlargement or air demand reduction can not be modified, the parameter of the second-major influence on the process performance should be considered. For instance, the PSA operating temperature can not be adjusted in the standard industrial applications since units are mostly placed outdoors or inside the unheated industrial halls. Hence, according to Tab. 7-1, in order to reduce the air demand figures during the nitrogen generation at purity level of 1000 ppm O2, the adjustment of the cutting time to 10 s shall be performed. It is necessary to highlight that all performance intensification measures presented here were studied separately, while all other process conditions were following the reference state. Since the PSA dynamic behaviour is practically responsive to every variation of process conditions and cycle organisation strategy, a multi-parameter optimisation should be executed to demonstrate the overall optimum of PSA performance indicators. Nevertheless, such an approach can be executed with the validated mathematical model of the PSA plant, and therefore depends only on computation time and capacity. Tab. 7-2 PSA operating guidelines with a focus on the process intensification; here T+B indicates Top/Top + Bottom/Bottom pressure equalisation strategy Priority Operating temperature [°C] Half-cycle time [s] Equalisation time [s] Purge time [s] Purge flowrate [m3n/h] Cutting time [s] Increasing the productivity Decreasing the air demand 20 20 20 60 60 60 1 1 1 59 59 59 Purity [ppm O2] 1000 100 10 1000 100 10 20 20 60 60 1 1 59 59 0.0485 0.0727 0 0 20 60 1 44 0.0650 0.0485 0.0485 0 0 0 Adsorption pressure [bar abs] 10* 8 8 8 6* 6* Production time / Blow-down time [s] 59 / 59 59 / 59 59 / 44 59 / 59 59 / 59 59 / 59 Equalisation strategy T+B T+B T+B T+B T+B T+B Purge proportionality factor [%] 40 60* 40 40 40 40 0.0485 Backflow Yes Yes Yes Yes Yes Yes 15* * a factor that was altered in relation to the reference process conditionsPDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |