PDF Publication Title:

Text from PDF Page: 107

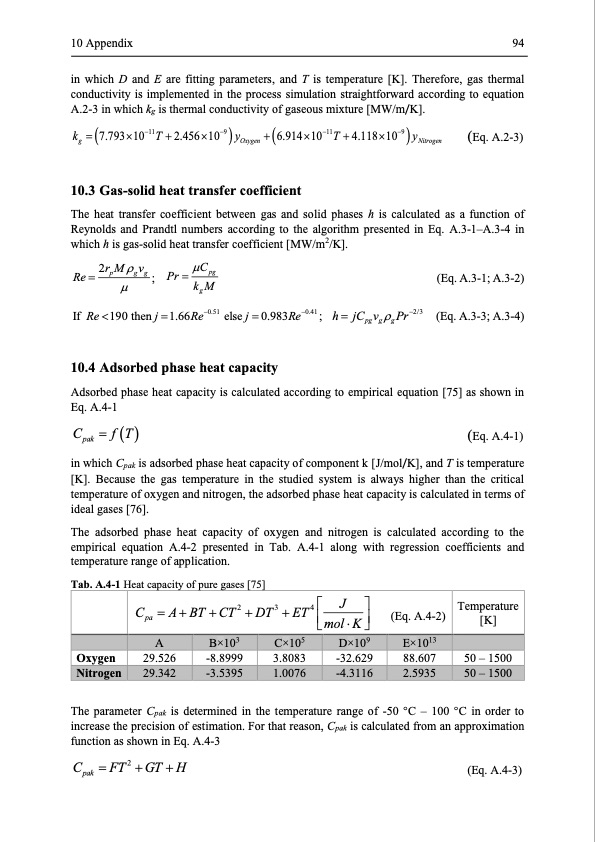

10 Appendix 94 in which D and E are fitting parameters, and T is temperature [K]. Therefore, gas thermal conductivity is implemented in the process simulation straightforward according to equation A.2-3 in which kg is thermal conductivity of gaseous mixture [MW/m/K]. kg = (7.79310−11T + 2.45610−9 )yOxygen + (6.91410−11T + 4.11810−9 )yNitrogen (Eq. A.2-3) 10.3 Gas-solid heat transfer coefficient The heat transfer coefficient between gas and solid phases h is calculated as a function of Reynolds and Prandtl numbers according to the algorithm presented in Eq. A.3-1–A.3-4 in which h is gas-solid heat transfer coefficient [MW/m2/K]. Re= 2rpMgvg ; Pr = Cpg (Eq.A.3-1;A.3-2) kgM If Re 190 then j =1.66Re−0.51 else j = 0.983Re−0.41 ; h = jCpgvg g Pr−2/3 (Eq. A.3-3; A.3-4) 10.4 Adsorbed phase heat capacity Adsorbed phase heat capacity is calculated according to empirical equation [75] as shown in Eq. A.4-1 Cpak =f(T) (Eq. A.4-1) in which Cpak is adsorbed phase heat capacity of component k [J/mol/K], and T is temperature [K]. Because the gas temperature in the studied system is always higher than the critical temperature of oxygen and nitrogen, the adsorbed phase heat capacity is calculated in terms of ideal gases [76]. The adsorbed phase heat capacity of oxygen and nitrogen is calculated according to the empirical equation A.4-2 presented in Tab. A.4-1 along with regression coefficients and temperature range of application. Tab. A.4-1 Heat capacity of pure gases [75] Oxygen 29.526 -8.8999 3.8083 -32.629 88.607 50 – 1500 The parameter Cpak is determined in the temperature range of -50 °C – 100 °C in order to increase the precision of estimation. For that reason, Cpak is calculated from an approximation function as shown in Eq. A.4-3 Cpak =FT2 +GT+H C =A+BT+CT2+DT3+ET4 J pa mol K (Eq. A.4-2) Temperature [K] A B×103 C×105 D×109 E×1013 Nitrogen 29.342 -3.5395 1.0076 -4.3116 2.5935 50 – 1500 (Eq. A.4-3)PDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |