PDF Publication Title:

Text from PDF Page: 108

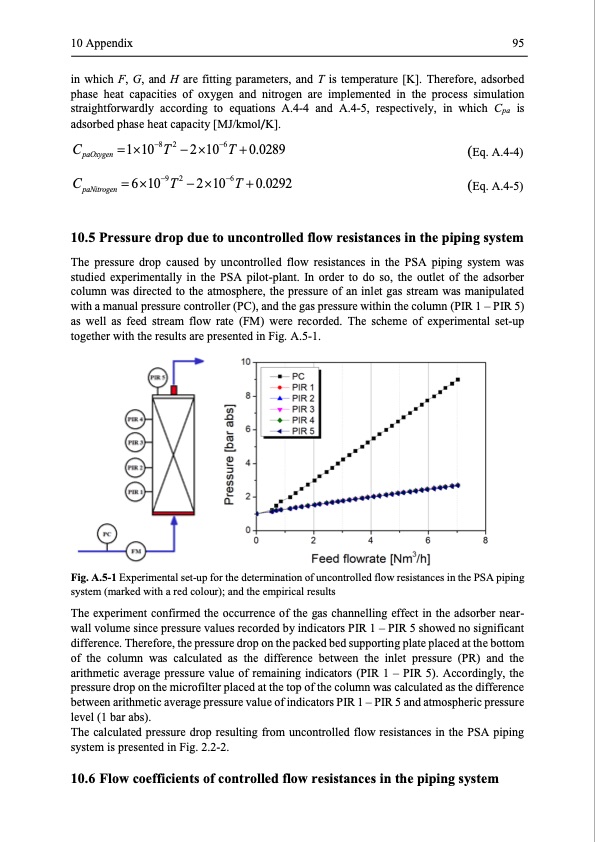

10 Appendix 95 in which F, G, and H are fitting parameters, and T is temperature [K]. Therefore, adsorbed phase heat capacities of oxygen and nitrogen are implemented in the process simulation straightforwardly according to equations A.4-4 and A.4-5, respectively, in which Cpa is adsorbed phase heat capacity [MJ/kmol/K]. CpaOxygen =110−8T2 −210−6T +0.0289 CpaNitrogen =610−9T2 −210−6T +0.0292 (Eq. A.4-4) (Eq. A.4-5) 10.5 Pressure drop due to uncontrolled flow resistances in the piping system The pressure drop caused by uncontrolled flow resistances in the PSA piping system was studied experimentally in the PSA pilot-plant. In order to do so, the outlet of the adsorber column was directed to the atmosphere, the pressure of an inlet gas stream was manipulated with a manual pressure controller (PC), and the gas pressure within the column (PIR 1 – PIR 5) as well as feed stream flow rate (FM) were recorded. The scheme of experimental set-up together with the results are presented in Fig. A.5-1. Fig. A.5-1 Experimental set-up for the determination of uncontrolled flow resistances in the PSA piping system (marked with a red colour); and the empirical results The experiment confirmed the occurrence of the gas channelling effect in the adsorber near- wall volume since pressure values recorded by indicators PIR 1 – PIR 5 showed no significant difference. Therefore, the pressure drop on the packed bed supporting plate placed at the bottom of the column was calculated as the difference between the inlet pressure (PR) and the arithmetic average pressure value of remaining indicators (PIR 1 – PIR 5). Accordingly, the pressure drop on the microfilter placed at the top of the column was calculated as the difference between arithmetic average pressure value of indicators PIR 1 – PIR 5 and atmospheric pressure level (1 bar abs). The calculated pressure drop resulting from uncontrolled flow resistances in the PSA piping system is presented in Fig. 2.2-2. 10.6 Flow coefficients of controlled flow resistances in the piping systemPDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |