PDF Publication Title:

Text from PDF Page: 109

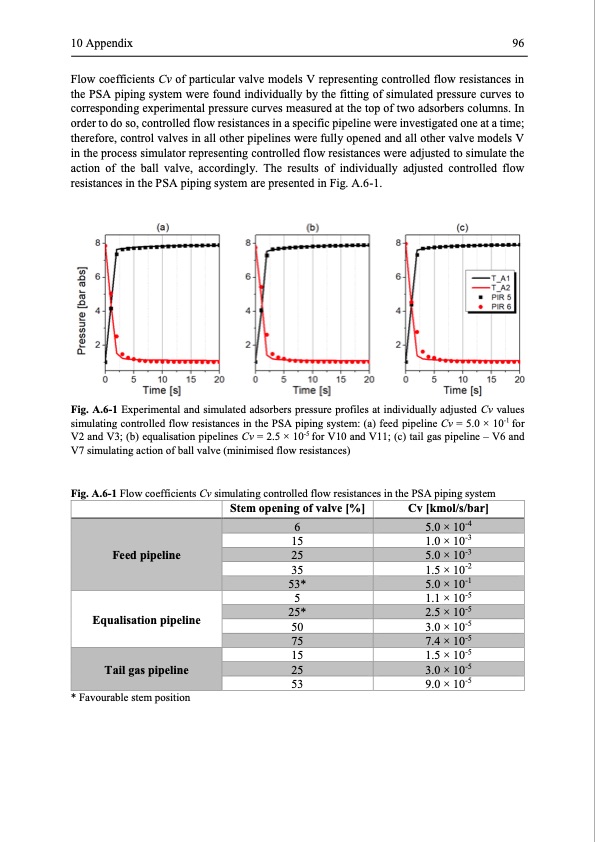

10 Appendix 96 Flow coefficients Cv of particular valve models V representing controlled flow resistances in the PSA piping system were found individually by the fitting of simulated pressure curves to corresponding experimental pressure curves measured at the top of two adsorbers columns. In order to do so, controlled flow resistances in a specific pipeline were investigated one at a time; therefore, control valves in all other pipelines were fully opened and all other valve models V in the process simulator representing controlled flow resistances were adjusted to simulate the action of the ball valve, accordingly. The results of individually adjusted controlled flow resistances in the PSA piping system are presented in Fig. A.6-1. Fig. A.6-1 Experimental and simulated adsorbers pressure profiles at individually adjusted Cv values simulating controlled flow resistances in the PSA piping system: (a) feed pipeline Cv = 5.0 Cv = 2.5 Fig. A.6-1 Flow coefficients Cv simulating controlled flow resistances in the PSA piping system × 10-1 for V2 and V3; (b) equalisation pipelines × 10-5 for V10 and V11; (c) tail gas pipeline – V6 and V7 simulating action of ball valve (minimised flow resistances) 5.0 × 10-4 25 5.0 × 10-3 Feed pipeline 6 5.0 × 10-1 53* 25* 2.5 × 10-5 Equalisation pipeline * Favourable stem position Stem opening of valve [%] 15 35 5 50 15 53 Cv [kmol/s/bar] 1.0 × 10-3 1.5 × 10-2 1.1 × 10-5 3.0 × 10-5 1.5 × 10-5 9.0 × 10-5 75 7.4 × 10-5 25 3.0 × 10-5 Tail gas pipelinePDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |