PDF Publication Title:

Text from PDF Page: 112

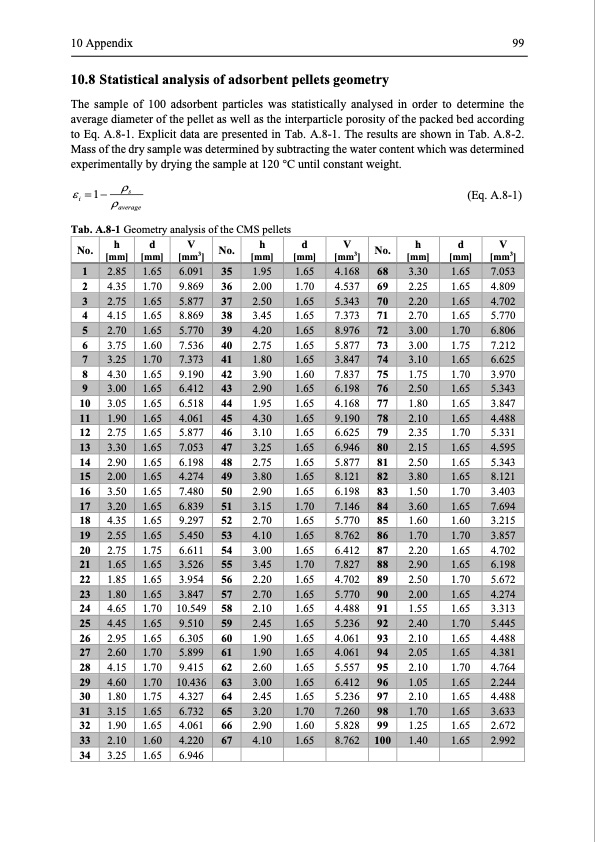

10 Appendix 99 10.8 Statistical analysis of adsorbent pellets geometry The sample of 100 adsorbent particles was statistically analysed in order to determine the average diameter of the pellet as well as the interparticle porosity of the packed bed according to Eq. A.8-1. Explicit data are presented in Tab. A.8-1. The results are shown in Tab. A.8-2. Mass of the dry sample was determined by subtracting the water content which was determined experimentally by drying the sample at 120 °C until constant weight. i =1− s (Eq. A.8-1) average Tab. A.8-1 Geometry analysis of the CMS pellets No. h d V No. h d V No. h d V [mm] [mm] [mm3] 35 9.869 36 37 8.869 38 39 7.536 40 41 9.190 42 43 6.518 44 45 5.877 46 47 6.198 48 49 7.480 50 51 9.297 52 53 6.611 54 55 3.954 56 57 10.549 58 59 6.305 60 61 9.415 62 63 4.327 64 65 4.061 66 67 6.946 [mm] 2.00 3.45 2.75 3.90 1.95 3.10 2.75 2.90 2.70 3.00 2.20 2.10 1.90 2.60 2.45 2.90 [mm] 1.70 1.65 1.65 1.60 1.65 1.65 1.65 1.65 1.65 1.65 1.65 1.65 1.65 1.65 1.65 1.60 [mm3] 4.537 7.373 5.877 7.837 4.168 6.625 5.877 6.198 5.770 6.412 4.702 4.488 4.061 5.557 5.236 5.828 [mm] [mm] [mm3] 4.809 5.770 7.212 3.970 3.847 5.331 5.343 3.403 3.215 4.702 5.672 3.313 4.488 4.764 4.488 2.672 2.85 1.65 6.091 1.95 1.65 4.168 3.30 1.65 7.053 1 2 4.35 1.70 3 4 4.15 1.65 5 6 3.75 1.60 7 8 4.30 1.65 9 10 3.05 1.65 11 12 2.75 1.65 13 14 2.90 1.65 15 16 3.50 1.65 17 18 4.35 1.65 19 20 2.75 1.75 21 22 1.85 1.65 23 24 4.65 1.70 25 26 2.95 1.65 27 28 4.15 1.70 29 30 1.80 1.75 31 32 1.90 1.65 33 34 3.25 1.65 68 69 2.25 1.65 70 71 2.70 1.65 72 73 3.00 1.75 74 75 1.75 1.70 76 77 1.80 1.65 78 79 2.35 1.70 80 81 2.50 1.65 82 83 1.50 1.70 84 85 1.60 1.60 86 87 2.20 1.65 88 89 2.50 1.70 90 91 1.55 1.65 92 93 2.10 1.65 94 95 2.10 1.70 96 97 2.10 1.65 98 99 1.25 1.65 100 2.75 1.65 5.877 2.50 1.65 5.343 2.20 1.65 4.702 2.70 1.65 5.770 4.20 1.65 8.976 3.00 1.70 6.806 3.25 1.70 7.373 1.80 1.65 3.847 3.10 1.65 6.625 3.00 1.65 6.412 2.90 1.65 6.198 2.50 1.65 5.343 1.90 1.65 4.061 4.30 1.65 9.190 2.10 1.65 4.488 3.30 1.65 7.053 3.25 1.65 6.946 2.15 1.65 4.595 2.00 1.65 4.274 3.80 1.65 8.121 3.80 1.65 8.121 3.20 1.65 6.839 3.15 1.70 7.146 3.60 1.65 7.694 2.55 1.65 5.450 4.10 1.65 8.762 1.70 1.70 3.857 1.65 1.65 3.526 3.45 1.70 7.827 2.90 1.65 6.198 1.80 1.65 3.847 2.70 1.65 5.770 2.00 1.65 4.274 4.45 1.65 9.510 2.45 1.65 5.236 2.40 1.70 5.445 2.60 1.70 5.899 1.90 1.65 4.061 2.05 1.65 4.381 4.60 1.70 10.436 3.00 1.65 6.412 1.05 1.65 2.244 3.15 1.65 6.732 3.20 1.70 7.260 1.70 1.65 3.633 2.10 1.60 4.220 4.10 1.65 8.762 1.40 1.65 2.992PDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |