PDF Publication Title:

Text from PDF Page: 113

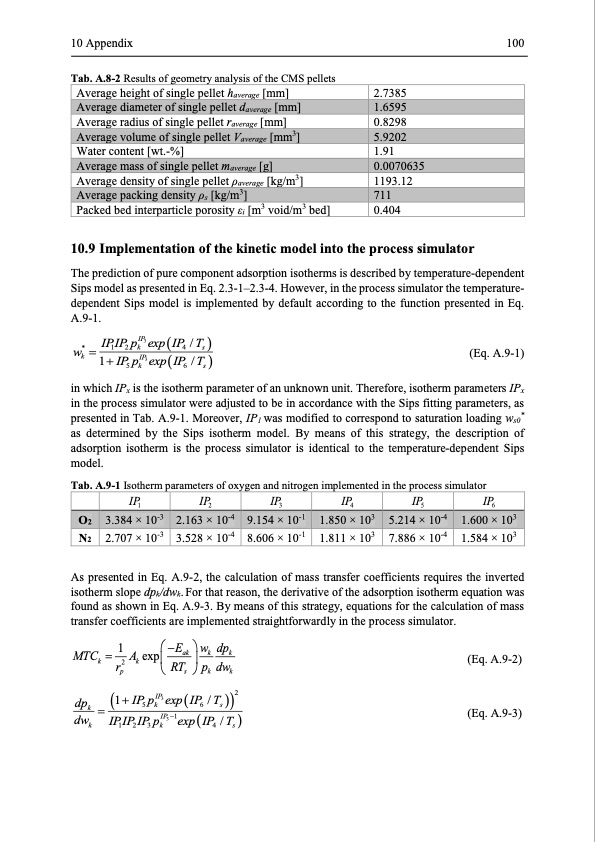

10 Appendix Tab. A.8-2 Results of geometry analysis of the CMS pellets Average height of single pellet haverage [mm] Average radius of single pellet raverage [mm] Water content [wt.-%] Average density of single pellet ρaverage [kg/m3] Packed bed interparticle porosity εi [m3 void/m3 bed] 100 2.7385 0.8298 1.91 1193.12 0.404 Average diameter of single pellet daverage [mm] 1.6595 Average volume of single pellet Vaverage [mm3] 5.9202 Average mass of single pellet maverage [g] 0.0070635 Average packing density ρs [kg/m3] 711 10.9 Implementation of the kinetic model into the process simulator The prediction of pure component adsorption isotherms is described by temperature-dependent Sips model as presented in Eq. 2.3-1–2.3-4. However, in the process simulator the temperature- dependent Sips model is implemented by default according to the function presented in Eq. A.9-1. (Eq. A.9-1) in which IPx is the isotherm parameter of an unknown unit. Therefore, isotherm parameters IPx in the process simulator were adjusted to be in accordance with the Sips fitting parameters, as presented in Tab. A.9-1. Moreover, IP1 was modified to correspond to saturation loading ws0* as determined by the Sips isotherm model. By means of this strategy, the description of adsorption isotherm is the process simulator is identical to the temperature-dependent Sips model. Tab. A.9-1 Isotherm parameters of oxygen and nitrogen implemented in the process simulator IP IP IP IP IP IP O2 N2 As presented in Eq. A.9-2, the calculation of mass transfer coefficients requires the inverted isotherm slope dpk/dwk. For that reason, the derivative of the adsorption isotherm equation was found as shown in Eq. A.9-3. By means of this strategy, equations for the calculation of mass transfer coefficients are implemented straightforwardly in the process simulator. 3 IPIP pIP exp(IP /T ) w*=12k 4s 3 k 1+IPpIPexp(IP /T) 5k6s 123456 3.384 × 10-3 2.707 × 10-3 2.163 × 10-4 3.528 × 10-4 9.154 × 10-1 8.606 × 10-1 5.214 × 10-4 7.886 × 10-4 1.600 × 103 1.811 × 103 1.584 × 103 MTC = 1 A exp−Eak wk dpk k r2 k RT p dw (Eq.A.9-2) pskk 3 dw IPIPIPpIP−1exp(IP /T) k123k4s 1+IPpIPexp(IP /T) dp( )2 k= 5k6s (Eq. A.9-3) 3 1.850 × 103PDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |