PDF Publication Title:

Text from PDF Page: 007

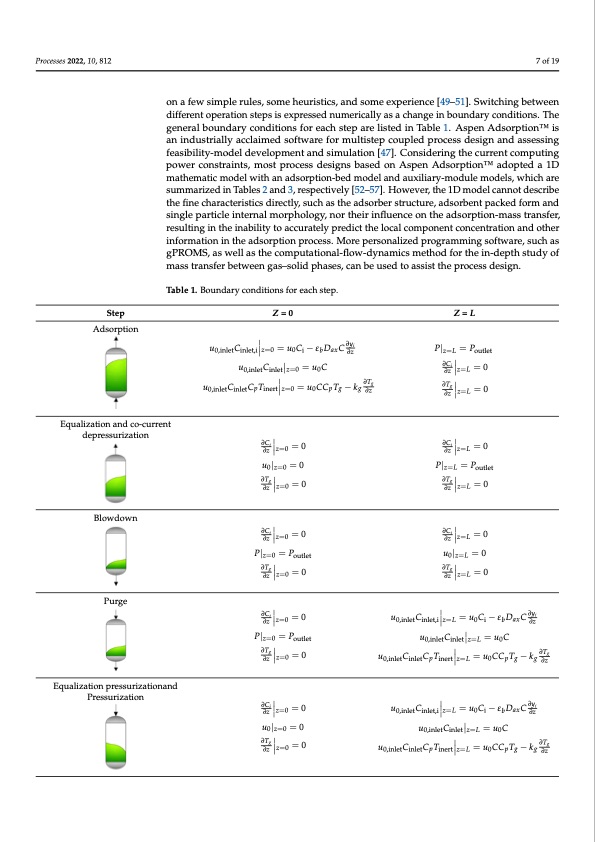

ance ∂𝑡 𝜀 ∂𝑡 ∂𝑧 ∂𝑧 2.5. One-Dimensional Process Model Processes 2022, 10, 812 Usually, there are five basic cycle steps associated with any PSA process: adsorption, pressure equalization, purge/rinse, co-current or counter-current depressurization (blow- down) and re-pressurization steps, which can be scheduled in many different ways for a typical PSA process with multiple beds [48]. Many previous works reported approaches their sequence, and the number of beds, and then following a systematic procedure based on a few simple rules, some heuristics, and some experience [49–51]. Switching between onadfieifwferseinmntpolpeperruraltetiso,nsosmtepepshieisuereixsptircess,saenddnsuomerieicxaplleyriaeasnscaec[h4a9an–n5g1e].inSwboiotucnhndidnagrybectownedeitntions. diffeTrehnetgoepneerraratilobnosutnenpdsariysyecxopnrdeisitsieodnsnfufomreraichalslsyteapsarecehlaisntegededinbToaubnled1a1r.yAcsopnednitAiodnso.rTphtieionTM geneisrsaalnbioinudnudsatriyialclyoynadccictliaoinmsefdorsoefatwcwharsreteefporamrmeulilstitisetdepincoTuapbpled1.prAroscpesessns dAedsisgonrpatnidodnaTMsseissing an infedaussibtrililiaitlyly-maocodcdlealimdevdelslopftmweanrtet afnonrdmsiumltuislataetipionco[u47p7]l.eCdCopnrsosicdesrsindgesthihgencaunrrdrenantstsceosmsinpguting feasibility-model development and simulation [47]. Considering the current computing feasipboilwiteyer-mcondsetlradaienvtses,lompomosetnptraoncedessimdeusliagtniosnb[a4s7e]d. CoonnAsisdspeerningAdtdhseorcputriroenTMt coadmdoputeteidnga 1D power constraints, most process designs based on Aspen AdsorptionTM adopted a 1D powmeratcthoenmstartaticnmtms,omdeolswt ipithrhoacaenssadseosripgtniosnb-abseedmoonodAelspanend Aaudxsioliraprtyi-omnoTModualdeomptoedelals,1wDhich mathematic model with an adsorption-bed model and auxiliary-module models, which mathaerme sautimc moadriezlewditnhTaanbaleds2oarnpdtioTna-bled3m, roedspelecatnivdealyux[i5l2ia–r5y7-]m. Hodouwlevmeor,dtehles,1wDhmichodaerlecan- are summarized in Table 2 and Table 3, respectively [52–57]. However, the 1D model can- summnoatridzesdcirnibTeabthles f2inaendch3a, reascptercitsitviceslyd[5ir2e–c5tl7y]., Hsuocwheavsert,htheea1dDsomrboedrelstcrauncntuotred,eascdrsiboerbent not describe the fine characteristics directly, such as the adsorber structure, adsorbent the fipnaeckchedarfaocrtmeriastnicdssdinirgelcetlpy,asrutichleaisntheernaadlsmorobreprhsotrlougctyu,rneo, ardthsoerirbeinftlupeanckcedonfotrhmeanddsorp- packed form and single particle internal morphology, nor their influence on the adsorp- Purge | z==0 =00 ∂z 𝜕𝜕𝜕𝜕𝑧𝑧𝑧𝑧 Purge 𝜕𝜕𝜕𝜕𝐶𝐶𝐶𝐶 𝜕𝜕𝜕𝜕𝑧𝑧𝑧𝑧∂z z=0 = 0 𝜕𝜕𝜕𝜕𝑦𝑦𝑦𝑦 𝜕𝜕𝜕𝜕𝑧𝑧𝑧𝑧8 of 19 Equalization pressuriza- tion 0 p g g for a complex PSA-cycle scheduling, involving a priori specification of the cycle steps, single particle internal morphology, nor their influence on the adsorption-mass transfer, tion-mass transfer, resulting in the inability to accurately predict the local component con- resulting in the inability to accurately predict the local component concentration and other centration and other information in the adsorption process. More personalized program- information in the adsorption process. More personalized programming software, such as 0|z=0 ∂T |z=L outlet 𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇 𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇 𝜕𝜕𝜕𝜕𝑧𝑧𝑧𝑧∂z ∂T g |=0=0 = 0 |g ==00 z= 0 z = L ∂z 𝜕𝜕𝜕𝜕𝑧𝑧𝑧𝑧 7 of 19 ming software, such as gPROMS, as well as the computational-flow-dynamics method for gPROMS, as well as the computational-flow-dynamics method for the in-depth study of the in-depth study of mass transfer between gas–solid phases, can be used to assist the mass transfer between gas–solid phases, can be used to assist the process design. process design. Step Adsorption Table 1. Boundary conditions for each step. Table 1. Boundary conditions for each step. Z =Z= 0= 0 0,inlet inlet,i z=0 0 i b Z =ZL= L Adsorption 𝜕𝜕𝑦𝑦 𝜕𝜕 𝑦𝑦 𝑃 | = 𝑃 𝑃𝑃𝑃| =𝑃𝑃𝑃 P| ∂Ci | = 0 ∂yi =𝑢𝑢𝑢𝑢 𝐶𝐶𝐶𝐶 −𝜀𝜀𝜀𝜀 𝐷𝐷𝐷𝐷 𝐶𝐶𝐶𝐶 𝑢𝑢𝑢𝑢 𝐶𝐶𝐶𝐶 | ,u C, =uC −ε DaxC 𝜕𝜕𝜕𝜕𝑧𝑧∂𝑧𝑧z 𝜕𝜕𝜕𝜕 𝑇𝑇𝑇𝑇 ∂ T 𝜕𝜕𝜕𝜕𝑧𝑧𝑧𝑧 P 𝑢𝑢𝑢𝑢 𝐶𝐶𝐶𝐶 | = 𝑢𝑢𝑢𝑢 𝐶𝐶𝐶𝐶 ,u0,inletCinletz=0 =u0C 𝜕𝐶 𝜕𝜕𝜕𝐶𝐶𝐶 u0𝐶𝐶𝐶𝐶,inletC𝐶𝐶𝐶𝐶inl𝑇𝑇𝑇𝑇etCpT|inert=z=0𝑢𝑢𝑢𝑢=𝐶𝐶𝐶𝐶u𝐶𝐶𝐶𝐶0C𝑇𝑇𝑇𝑇Cp−Tg𝑘𝑘𝑘𝑘−kg 𝑢𝑢𝑢𝑢 , Processes 2022, 10, x FOR PEER REVIEW 𝜕𝑧∂z z=0 = 0 Table 2. Mathematical model of 1D non-isothermal adsorption bed. Equation ∂𝐶 +1−𝜀𝜌 ∂𝑤 −𝐷 ∂𝐶 +∂𝑢𝐶=0 Equalization and co-cur- rent depressurization depressurization ∂|C|i =0 ∂Ci | =0 𝜕 𝜕 𝜕 𝜕 𝑧 𝑧 𝑧 𝑧 ∂ z z = 0 = 0 ∂ z 𝜕 𝜕 𝜕 𝜕 z 𝑧 =𝑧 𝑧 𝑧 L = 0 g ∂z 𝜕𝜕𝜕𝜕 𝑇𝑇𝑇𝑇 = P z=L outlet =0 ∂Tg |=0=0 𝜕𝜕𝜕z𝑧=𝑧𝑧L ∂z 𝜕𝑧 z=L ∂z 𝜕𝜕𝜕𝜕𝑧𝑧𝑧𝑧 Equalization and co-current 𝜕𝜕𝜕𝜕𝐶𝐶𝐶𝐶 𝜕𝜕𝜕𝜕𝐶𝐶𝐶𝐶 𝑢𝑢𝑢𝑢 | = 0 u = 0 𝑃𝑃𝑃𝑃| = 𝑃𝑃𝑃𝑃 =P Blolowdown 𝜕𝜕𝜕𝜕𝐶𝐶𝐶𝐶 𝜕𝜕𝜕𝜕 𝐶𝐶𝐶𝐶 ∂|C| i = 0 ∂Ci | =0 =0 𝜕𝜕𝜕𝜕𝑧𝑧𝑧𝑧∂z z=0 ∂z 𝜕𝜕𝜕𝜕z𝑧=𝑧𝑧𝑧L 𝑃𝑃𝑃𝑃| = 𝑃𝑃𝑃𝑃 P| =P 𝑢𝑢𝑢𝑢 | = 0 u | =0 z=0 outlet ∂Tg 0 z=L 𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇 𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇 𝜕𝜕𝜕𝜕𝑧𝑧𝑧𝑧∂z ∂Tg z=L|= 0= 0 ∂|C|i = 0 𝐶𝐶𝐶 𝑃𝑃𝑃𝑃| =𝑃𝑃𝑃𝑃 P| =P 𝑢𝑢𝑢𝑢,𝐶𝐶𝐶𝐶| =𝑢𝑢𝑢𝑢𝐶𝐶𝐶𝐶 z=0 outlet ∂Tg u C 𝐶𝐶𝐶𝐶 C T𝐶𝐶𝐶𝐶 𝑇𝑇𝑇𝑇 𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇 𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇 𝜕𝜕𝜕𝜕𝑧𝑧𝑧𝑧 ∂zz=0 u 𝑢𝑢𝑢𝑢 0,inl,etinletp inertz=L ∂z 𝜕𝜕𝜕𝜕𝑧𝑧𝑧𝑧 𝜕𝑦 𝜕𝑧 | ==00 ∂Tg | = u=C𝑢𝑢𝑢𝑢C𝐶𝐶𝐶𝐶T𝐶𝐶𝐶𝐶−𝑇𝑇𝑇𝑇k−𝑘𝑘𝑘𝑘 i 𝑢𝑢𝑢𝑢,𝐶𝐶𝐶𝐶,| = 𝑢𝑢𝑢𝑢𝐶𝐶𝐶𝐶 − 𝜀𝜀𝜀𝜀𝐷𝐷𝐷𝐷∂y𝐶 ,, ,, u0,inletCinlet,iz=L = u0Ci − εbDaxC ∂z ,,C =u C 0,inlet inlet z=L 0 Equalization pressurizationand 𝜕𝐶 𝜕𝑧∂Ci z=0 = 0 and Pressurization | =0 𝑢 𝐶 | =𝑢𝐶−𝜀𝐷 𝐶 , , Pressurization u0,inletCinlet,iz=L = u0Ci −εbDaxC∂yi ∂z 𝑢|=0 𝑢𝐶|=𝑢𝐶 ∂z , 𝜕𝑇u0|z=0 = 0 u0,inletCinletz=L = u0C 𝜕𝑇 g=0 ∂T| 𝑢 𝐶𝐶𝑇|=𝑢𝐶𝐶𝑇−𝑘 , u0,inletCinletCpTinertz=L = u0CCpTg − kg ∂z 𝜕𝑧 ∂Tg Category Componentmassbal-PDF Image | Numerical Research on the Pressure Swing Adsorption Process

PDF Search Title:

Numerical Research on the Pressure Swing Adsorption ProcessOriginal File Name Searched:

processes-10-00812-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |