PDF Publication Title:

Text from PDF Page: 143

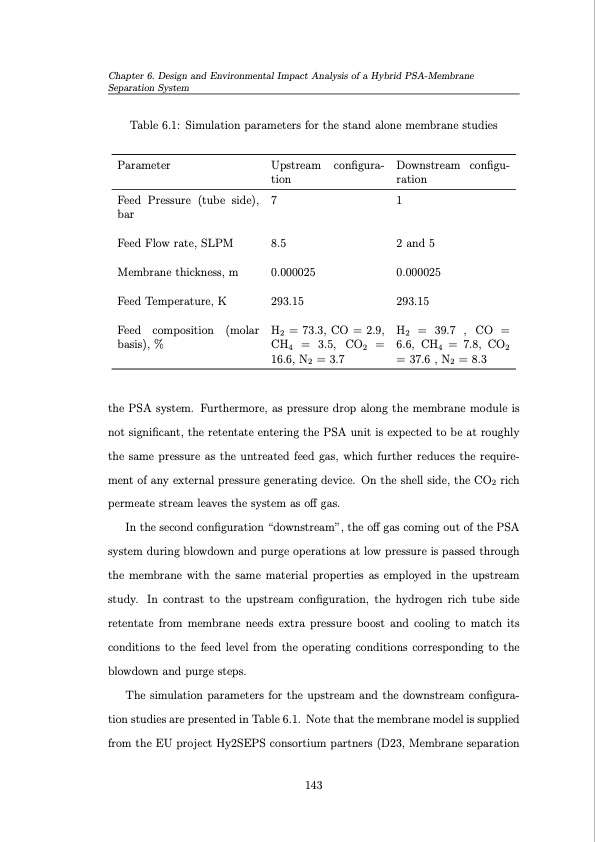

Chapter 6. Design and Environmental Impact Analysis of a Hybrid PSA-Membrane Separation System Table 6.1: Simulation parameters for the stand alone membrane studies Parameter Feed Pressure (tube side), bar Feed Flow rate, SLPM Membrane thickness, m Feed Temperature, K Feed composition (molar basis), % Upstream configura- tion 7 8.5 0.000025 293.15 H2 = 73.3, CO = 2.9, CH4 = 3.5, CO2 = 16.6,N2 =3.7 Downstream configu- ration 1 2 and 5 0.000025 293.15 H2 = 39.7 , CO = 6.6, CH4 = 7.8, CO2 =37.6,N2 =8.3 the PSA system. Furthermore, as pressure drop along the membrane module is not significant, the retentate entering the PSA unit is expected to be at roughly the same pressure as the untreated feed gas, which further reduces the require- ment of any external pressure generating device. On the shell side, the CO2 rich permeate stream leaves the system as off gas. In the second configuration “downstream”, the off gas coming out of the PSA system during blowdown and purge operations at low pressure is passed through the membrane with the same material properties as employed in the upstream study. In contrast to the upstream configuration, the hydrogen rich tube side retentate from membrane needs extra pressure boost and cooling to match its conditions to the feed level from the operating conditions corresponding to the blowdown and purge steps. The simulation parameters for the upstream and the downstream configura- tion studies are presented in Table 6.1. Note that the membrane model is supplied from the EU project Hy2SEPS consortium partners (D23, Membrane separation 143PDF Image | Operation and Control of Pressure Swing Adsorption Systems

PDF Search Title:

Operation and Control of Pressure Swing Adsorption SystemsOriginal File Name Searched:

Khajuria-H-2011-PhD-Thesis.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |