PDF Publication Title:

Text from PDF Page: 144

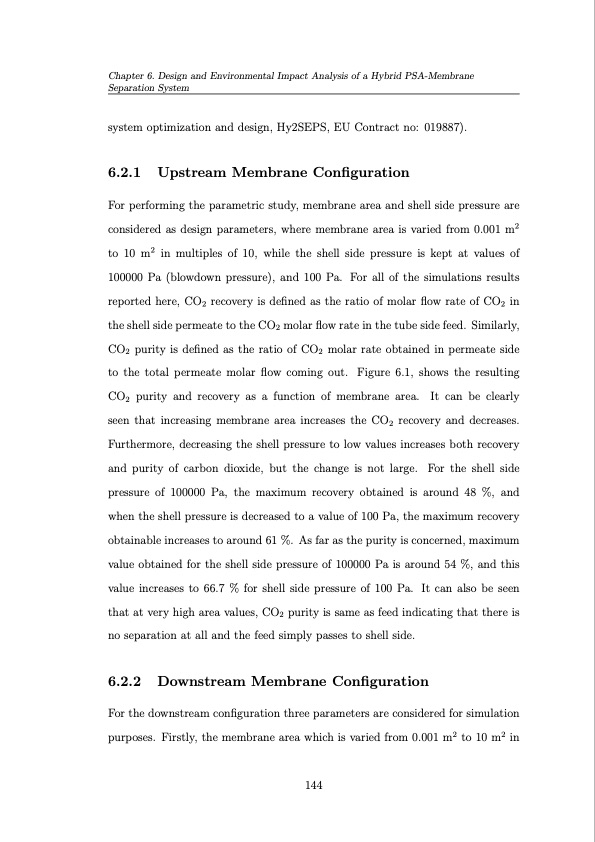

Chapter 6. Design and Environmental Impact Analysis of a Hybrid PSA-Membrane Separation System system optimization and design, Hy2SEPS, EU Contract no: 019887). 6.2.1 Upstream Membrane Configuration For performing the parametric study, membrane area and shell side pressure are considered as design parameters, where membrane area is varied from 0.001 m2 to 10 m2 in multiples of 10, while the shell side pressure is kept at values of 100000 Pa (blowdown pressure), and 100 Pa. For all of the simulations results reported here, CO2 recovery is defined as the ratio of molar flow rate of CO2 in the shell side permeate to the CO2 molar flow rate in the tube side feed. Similarly, CO2 purity is defined as the ratio of CO2 molar rate obtained in permeate side to the total permeate molar flow coming out. Figure 6.1, shows the resulting CO2 purity and recovery as a function of membrane area. It can be clearly seen that increasing membrane area increases the CO2 recovery and decreases. Furthermore, decreasing the shell pressure to low values increases both recovery and purity of carbon dioxide, but the change is not large. For the shell side pressure of 100000 Pa, the maximum recovery obtained is around 48 %, and when the shell pressure is decreased to a value of 100 Pa, the maximum recovery obtainable increases to around 61 %. As far as the purity is concerned, maximum value obtained for the shell side pressure of 100000 Pa is around 54 %, and this value increases to 66.7 % for shell side pressure of 100 Pa. It can also be seen that at very high area values, CO2 purity is same as feed indicating that there is no separation at all and the feed simply passes to shell side. 6.2.2 Downstream Membrane Configuration For the downstream configuration three parameters are considered for simulation purposes. Firstly, the membrane area which is varied from 0.001 m2 to 10 m2 in 144PDF Image | Operation and Control of Pressure Swing Adsorption Systems

PDF Search Title:

Operation and Control of Pressure Swing Adsorption SystemsOriginal File Name Searched:

Khajuria-H-2011-PhD-Thesis.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |