PDF Publication Title:

Text from PDF Page: 005

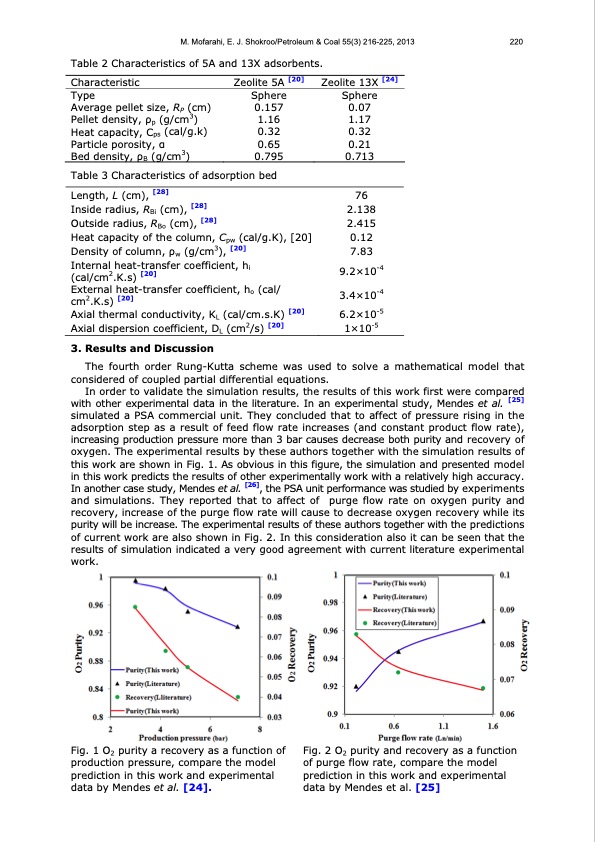

M. Mofarahi, E. J. Shokroo/Petroleum & Coal 55(3) 216-225, 2013 220 Table 2 Characteristics of 5A and 13X adsorbents. Characteristic Type Average pellet size, RP (cm) Pellet density, ρp (g/cm3) Heat capacity, Cps (cal/g.k) Particle porosity, α Bed density, ρB (g/cm3) Zeolite 5A [20] Sphere 0.157 1.16 0.32 0.65 0.795 Zeolite 13X [24] Sphere 0.07 1.17 0.32 0.21 0.713 76 2.138 2.415 0.12 7.83 9.2×10-4 3.4×10-4 6.2×10-5 1×10-5 Table 3 Characteristics of adsorption bed Length, L (cm), [28] Inside radius, RBi (cm), [28] Outside radius, RBo (cm), [28] Heat capacity of the column, Cpw (cal/g.K), [20] Density of column, ρw (g/cm3), [20] Internal heat-transfer coefficient, hi (cal/cm2.K.s) [20] External heat-transfer coefficient, ho (cal/ cm2.K.s) [20] Axial thermal conductivity, KL (cal/cm.s.K) [20] Axial dispersion coefficient, DL (cm2/s) [20] 3. Results and Discussion The fourth order Rung-Kutta scheme was used to solve a mathematical model that considered of coupled partial differential equations. In order to validate the simulation results, the results of this work first were compared with other experimental data in the literature. In an experimental study, Mendes et al. [25] simulated a PSA commercial unit. They concluded that to affect of pressure rising in the adsorption step as a result of feed flow rate increases (and constant product flow rate), increasing production pressure more than 3 bar causes decrease both purity and recovery of oxygen. The experimental results by these authors together with the simulation results of this work are shown in Fig. 1. As obvious in this figure, the simulation and presented model in this work predicts the results of other experimentally work with a relatively high accuracy. In another case study, Mendes et al. [26], the PSA unit performance was studied by experiments and simulations. They reported that to affect of purge flow rate on oxygen purity and recovery, increase of the purge flow rate will cause to decrease oxygen recovery while its purity will be increase. The experimental results of these authors together with the predictions of current work are also shown in Fig. 2. In this consideration also it can be seen that the results of simulation indicated a very good agreement with current literature experimental work. Fig. 1 O2 purity a recovery as a function of production pressure, compare the model prediction in this work and experimental data by Mendes et al. [24]. Fig. 2 O2 purity and recovery as a function of purge flow rate, compare the model prediction in this work and experimental data by Mendes et al. [25]PDF Image | PRESSURE SWING ADSORPTION PROCESSES FOR AIR SEPARATION WITH ZEOLITE

PDF Search Title:

PRESSURE SWING ADSORPTION PROCESSES FOR AIR SEPARATION WITH ZEOLITEOriginal File Name Searched:

pc_3_2013_javadi_221.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |