PDF Publication Title:

Text from PDF Page: 009

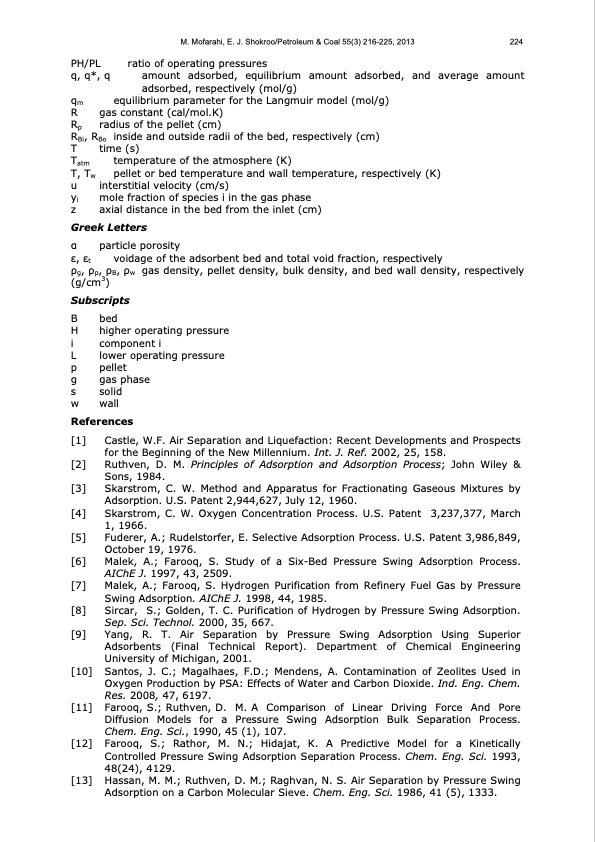

PH/PL q, q*, q M. Mofarahi, E. J. Shokroo/Petroleum & Coal 55(3) 216-225, 2013 224 ratio of operating pressures amount adsorbed, equilibrium amount adsorbed, and average amount adsorbed, respectively (mol/g) equilibrium parameter for the Langmuir model (mol/g) gas constant (cal/mol.K) radius of the pellet (cm) qm R Rp RBi, RBo inside and outside radii of the bed, respectively (cm) T Tatm T, Tw u yi z time (s) temperature of the atmosphere (K) pellet or bed temperature and wall temperature, respectively (K) interstitial velocity (cm/s) mole fraction of species i in the gas phase axial distance in the bed from the inlet (cm) Greek Letters α particle porosity ε, εt voidage of the adsorbent bed and total void fraction, respectively ρg, ρp, ρB, ρw gas density, pellet density, bulk density, and bed wall density, respectively (g/cm3) Subscripts B bed H higher operating pressure i component i L lower operating pressure p pellet g gas phase s solid w wall References [1] Castle, W.F. Air Separation and Liquefaction: Recent Developments and Prospects for the Beginning of the New Millennium. Int. J. Ref. 2002, 25, 158. [2] Ruthven, D. M. Principles of Adsorption and Adsorption Process; John Wiley & Sons, 1984. [3] Skarstrom, C. W. Method and Apparatus for Fractionating Gaseous Mixtures by Adsorption. U.S. Patent 2,944,627, July 12, 1960. [4] Skarstrom, C. W. Oxygen Concentration Process. U.S. Patent 3,237,377, March 1, 1966. [5] Fuderer, A.; Rudelstorfer, E. Selective Adsorption Process. U.S. Patent 3,986,849, October 19, 1976. [6] Malek, A.; Farooq, S. Study of a Six-Bed Pressure Swing Adsorption Process. AIChE J. 1997, 43, 2509. [7] Malek, A.; Farooq, S. Hydrogen Purification from Refinery Fuel Gas by Pressure Swing Adsorption. AIChE J. 1998, 44, 1985. [8] Sircar, S.; Golden, T. C. Purification of Hydrogen by Pressure Swing Adsorption. Sep. Sci. Technol. 2000, 35, 667. [9] Yang, R. T. Air Separation by Pressure Swing Adsorption Using Superior Adsorbents (Final Technical Report). Department of Chemical Engineering University of Michigan, 2001. [10] Santos, J. C.; Magalhaes, F.D.; Mendens, A. Contamination of Zeolites Used in Oxygen Production by PSA: Effects of Water and Carbon Dioxide. Ind. Eng. Chem. Res. 2008, 47, 6197. [11] Farooq, S.; Ruthven, D. M. A Comparison of Linear Driving Force And Pore Diffusion Models for a Pressure Swing Adsorption Bulk Separation Process. Chem. Eng. Sci., 1990, 45 (1), 107. [12] Farooq, S.; Rathor, M. N.; Hidajat, K. A Predictive Model for a Kinetically Controlled Pressure Swing Adsorption Separation Process. Chem. Eng. Sci. 1993, 48(24), 4129. [13] Hassan, M. M.; Ruthven, D. M.; Raghvan, N. S. Air Separation by Pressure Swing Adsorption on a Carbon Molecular Sieve. Chem. Eng. Sci. 1986, 41 (5), 1333.PDF Image | PRESSURE SWING ADSORPTION PROCESSES FOR AIR SEPARATION WITH ZEOLITE

PDF Search Title:

PRESSURE SWING ADSORPTION PROCESSES FOR AIR SEPARATION WITH ZEOLITEOriginal File Name Searched:

pc_3_2013_javadi_221.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |