PDF Publication Title:

Text from PDF Page: 008

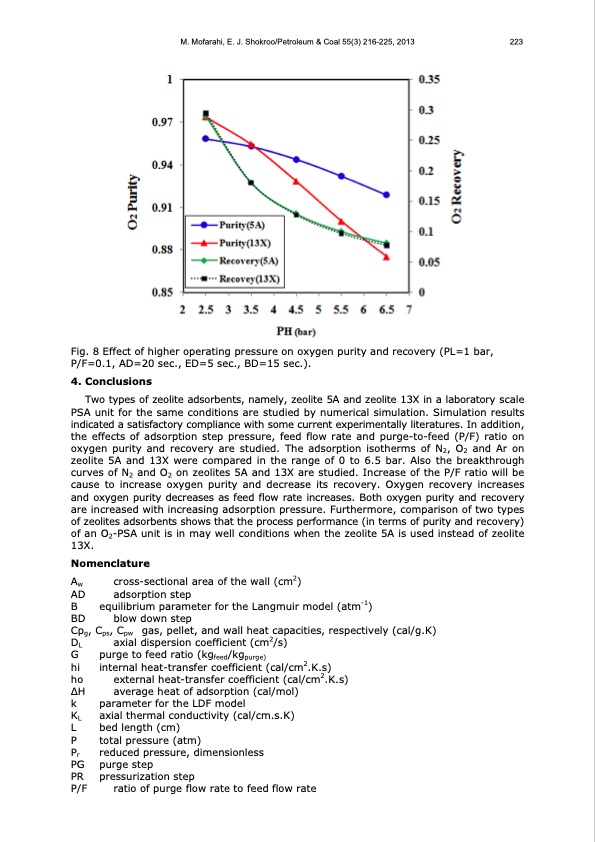

DL G hi ho ΔH k KL L P Pr PG PR P/F axial dispersion coefficient (cm2/s) purge to feed ratio (kgfeed/kgpurge) internal heat-transfer coefficient (cal/cm2.K.s) external heat-transfer coefficient (cal/cm2.K.s) average heat of adsorption (cal/mol) parameter for the LDF model axial thermal conductivity (cal/cm.s.K) bed length (cm) total pressure (atm) reduced pressure, dimensionless purge step pressurization step ratio of purge flow rate to feed flow rate M. Mofarahi, E. J. Shokroo/Petroleum & Coal 55(3) 216-225, 2013 223 Fig. 8 Effect of higher operating pressure on oxygen purity and recovery (PL=1 bar, P/F=0.1, AD=20 sec., ED=5 sec., BD=15 sec.). 4. Conclusions Two types of zeolite adsorbents, namely, zeolite 5A and zeolite 13X in a laboratory scale PSA unit for the same conditions are studied by numerical simulation. Simulation results indicated a satisfactory compliance with some current experimentally literatures. In addition, the effects of adsorption step pressure, feed flow rate and purge-to-feed (P/F) ratio on oxygen purity and recovery are studied. The adsorption isotherms of N2, O2 and Ar on zeolite 5A and 13X were compared in the range of 0 to 6.5 bar. Also the breakthrough curves of N2 and O2 on zeolites 5A and 13X are studied. Increase of the P/F ratio will be cause to increase oxygen purity and decrease its recovery. Oxygen recovery increases and oxygen purity decreases as feed flow rate increases. Both oxygen purity and recovery are increased with increasing adsorption pressure. Furthermore, comparison of two types of zeolites adsorbents shows that the process performance (in terms of purity and recovery) of an O2-PSA unit is in may well conditions when the zeolite 5A is used instead of zeolite 13X. Nomenclature adsorption step equilibrium parameter for the Langmuir model (atm-1) cross-sectional area of the wall (cm2) Aw AD B BD Cpg, Cps, Cpw gas, pellet, and wall heat capacities, respectively (cal/g.K) blow down stepPDF Image | PRESSURE SWING ADSORPTION PROCESSES FOR AIR SEPARATION WITH ZEOLITE

PDF Search Title:

PRESSURE SWING ADSORPTION PROCESSES FOR AIR SEPARATION WITH ZEOLITEOriginal File Name Searched:

pc_3_2013_javadi_221.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |