PDF Publication Title:

Text from PDF Page: 004

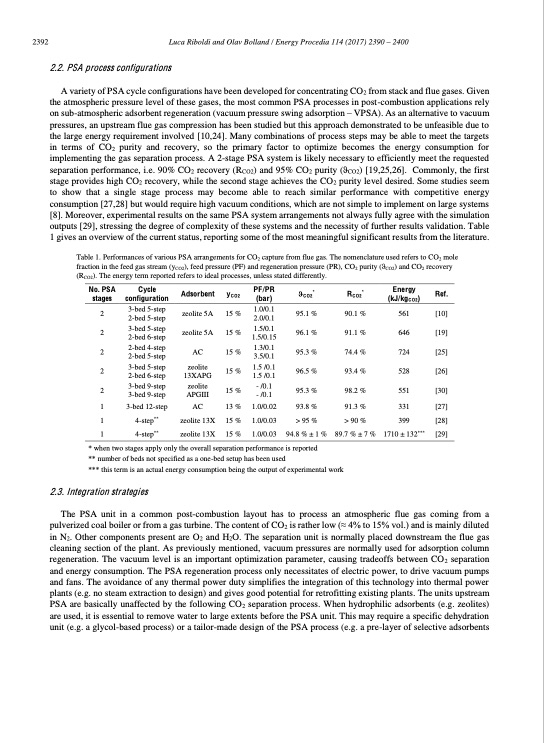

2392 Luca Riboldi and Olav Bolland / Energy Procedia 114 (2017) 2390 – 2400 2.2. PSA process configurations A variety of PSA cycle configurations have been developed for concentrating CO2 from stack and flue gases. Given the atmospheric pressure level of these gases, the most common PSA processes in post-combustion applications rely on sub-atmospheric adsorbent regeneration (vacuum pressure swing adsorption – VPSA). As an alternative to vacuum pressures, an upstream flue gas compression has been studied but this approach demonstrated to be unfeasible due to the large energy requirement involved [10,24]. Many combinations of process steps may be able to meet the targets in terms of CO2 purity and recovery, so the primary factor to optimize becomes the energy consumption for implementing the gas separation process. A 2-stage PSA system is likely necessary to efficiently meet the requested separation performance, i.e. 90% CO2 recovery (RCO2) and 95% CO2 purity (θCO2) [19,25,26]. Commonly, the first stage provides high CO2 recovery, while the second stage achieves the CO2 purity level desired. Some studies seem to show that a single stage process may become able to reach similar performance with competitive energy consumption [27,28] but would require high vacuum conditions, which are not simple to implement on large systems [8]. Moreover, experimental results on the same PSA system arrangements not always fully agree with the simulation outputs [29], stressing the degree of complexity of these systems and the necessity of further results validation. Table 1 gives an overview of the current status, reporting some of the most meaningful significant results from the literature. Table 1. Performances of various PSA arrangements for CO2 capture from flue gas. The nomenclature used refers to CO2 mole fraction in the feed gas stream (yCO2), feed pressure (PF) and regeneration pressure (PR), (RCO2). The energy term reported refers to ideal processes, unless stated differently. CO2 purity (θCO2) and CO2 recovery No. PSA stages 2 2 2 2 2 1 1 1 Cycle configuration 3-bed 5-step 2-bed 5-step 3-bed 5-step 2-bed 6-step 2-bed 4-step 2-bed 5-step 3-bed 5-step 2-bed 6-step 3-bed 9-step 3-bed 9-step 3-bed 12-step 4-step** 4-step** Adsorbent yCO2 zeolite 5A 15% zeolite 5A 15% AC 15% zeolite 15% 13XAPG zeolite 15% APGIII AC 13% zeolite 13X 15% zeolite 13X 15% PF/PR (bar) 1.0/0.1 2.0/0.1 1.5/0.1 1.5/0.15 1.3/0.1 3.5/0.1 1.5 /0.1 1.5 /0.1 - /0.1 - /0.1 1.0/0.02 1.0/0.03 1.0/0.03 θCO2* 95.1 % 96.1 % 95.3 % 96.5 % 95.3 % 93.8 % >95% 94.8 % ± 1 % RCO2* 90.1 % 91.1 % 74.4 % 93.4 % 98.2 % 91.3 % >90% 89.7 % ± 7 % Energy (kJ/kgCO2) Ref. 561 [10] 646 [19] 724 [25] 528 [26] 551 [30] 331 [27] 399 [28] 1710 ± 132*** [29] * when two stages apply only the overall separation performance is reported ** number of beds not specified as a one-bed setup has been used *** this term is an actual energy consumption being the output of experimental work 2.3. Integration strategies The PSA unit in a common post-combustion layout has to process an atmospheric flue gas coming from a pulverized coal boiler or from a gas turbine. The content of CO2 is rather low (≈ 4% to 15% vol.) and is mainly diluted in N2. Other components present are O2 and H2O. The separation unit is normally placed downstream the flue gas cleaning section of the plant. As previously mentioned, vacuum pressures are normally used for adsorption column regeneration. The vacuum level is an important optimization parameter, causing tradeoffs between CO2 separation and energy consumption. The PSA regeneration process only necessitates of electric power, to drive vacuum pumps and fans. The avoidance of any thermal power duty simplifies the integration of this technology into thermal power plants (e.g. no steam extraction to design) and gives good potential for retrofitting existing plants. The units upstream PSA are basically unaffected by the following CO2 separation process. When hydrophilic adsorbents (e.g. zeolites) are used, it is essential to remove water to large extents before the PSA unit. This may require a specific dehydration unit (e.g. a glycol-based process) or a tailor-made design of the PSA process (e.g. a pre-layer of selective adsorbentsPDF Image | Pressure Swing Adsorption (PSA) as CO2 Capture Technology

PDF Search Title:

Pressure Swing Adsorption (PSA) as CO2 Capture TechnologyOriginal File Name Searched:

PSA-co2-capture.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |