PDF Publication Title:

Text from PDF Page: 005

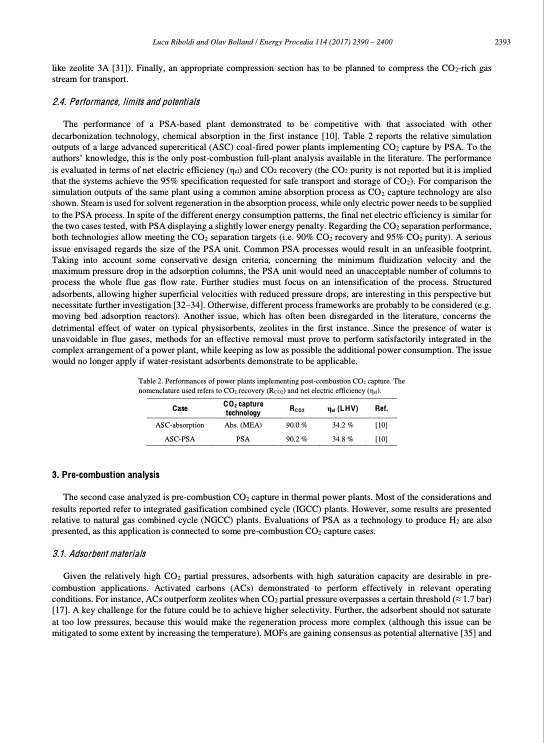

Luca Riboldi and Olav Bolland / Energy Procedia 114 (2017) 2390 – 2400 2393 like zeolite 3A [31]). Finally, an appropriate compression section has to be planned to compress the CO2-rich gas stream for transport. 2.4. Performance, limits and potentials The performance of a PSA-based plant demonstrated to be competitive with that associated with other decarbonization technology, chemical absorption in the first instance [10]. Table 2 reports the relative simulation outputs of a large advanced supercritical (ASC) coal-fired power plants implementing CO2 capture by PSA. To the authors’ knowledge, this is the only post-combustion full-plant analysis available in the literature. The performance is evaluated in terms of net electric efficiency (ηel) and CO2 recovery (the CO2 purity is not reported but it is implied that the systems achieve the 95% specification requested for safe transport and storage of CO2). For comparison the simulation outputs of the same plant using a common amine absorption process as CO2 capture technology are also shown. Steam is used for solvent regeneration in the absorption process, while only electric power needs to be supplied to the PSA process. In spite of the different energy consumption patterns, the final net electric efficiency is similar for the two cases tested, with PSA displaying a slightly lower energy penalty. Regarding the CO2 separation performance, both technologies allow meeting the CO2 separation targets (i.e. 90% CO2 recovery and 95% CO2 purity). A serious issue envisaged regards the size of the PSA unit. Common PSA processes would result in an unfeasible footprint. Taking into account some conservative design criteria, concerning the minimum fluidization velocity and the maximum pressure drop in the adsorption columns, the PSA unit would need an unacceptable number of columns to process the whole flue gas flow rate. Further studies must focus on an intensification of the process. Structured adsorbents, allowing higher superficial velocities with reduced pressure drops, are interesting in this perspective but necessitate further investigation [32–34]. Otherwise, different process frameworks are probably to be considered (e.g. moving bed adsorption reactors). Another issue, which has often been disregarded in the literature, concerns the detrimental effect of water on typical physisorbents, zeolites in the first instance. Since the presence of water is unavoidable in flue gases, methods for an effective removal must prove to perform satisfactorily integrated in the complex arrangement of a power plant, while keeping as low as possible the additional power consumption. The issue would no longer apply if water-resistant adsorbents demonstrate to be applicable. Table 2. Performances of power plants implementing post-combustion CO2 capture. The nomenclature used refers to CO2 recovery (RCO2) and net electric efficiency (ηel). Case ASC-absorption ASC-PSA 3. Pre-combustion analysis CO2 capture technology Abs. (MEA) PSA RCO2 90.0 % 90.2 % ηel (LHV) Ref. 34.2 % [10] 34.8 % [10] The second case analyzed is pre-combustion CO2 capture in thermal power plants. Most of the considerations and results reported refer to integrated gasification combined cycle (IGCC) plants. However, some results are presented relative to natural gas combined cycle (NGCC) plants. Evaluations of PSA as a technology to produce H2 are also presented, as this application is connected to some pre-combustion CO2 capture cases. 3.1. Adsorbent materials Given the relatively high CO2 partial pressures, adsorbents with high saturation capacity are desirable in pre- combustion applications. Activated carbons (ACs) demonstrated to perform effectively in relevant operating conditions. For instance, ACs outperform zeolites when CO2 partial pressure overpasses a certain threshold (≈ 1.7 bar) [17]. A key challenge for the future could be to achieve higher selectivity. Further, the adsorbent should not saturate at too low pressures, because this would make the regeneration process more complex (although this issue can be mitigated to some extent by increasing the temperature). MOFs are gaining consensus as potential alternative [35] andPDF Image | Pressure Swing Adsorption (PSA) as CO2 Capture Technology

PDF Search Title:

Pressure Swing Adsorption (PSA) as CO2 Capture TechnologyOriginal File Name Searched:

PSA-co2-capture.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |