PDF Publication Title:

Text from PDF Page: 007

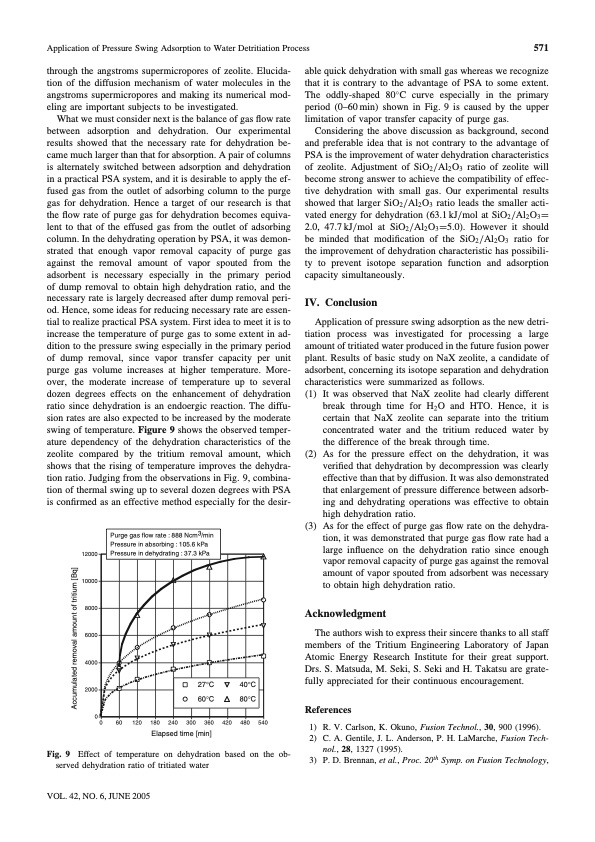

Application of Pressure Swing Adsorption to Water Detritiation Process 571 through the angstroms supermicropores of zeolite. Elucida- tion of the diffusion mechanism of water molecules in the angstroms supermicropores and making its numerical mod- eling are important subjects to be investigated. What we must consider next is the balance of gas flow rate between adsorption and dehydration. Our experimental results showed that the necessary rate for dehydration be- came much larger than that for absorption. A pair of columns is alternately switched between adsorption and dehydration in a practical PSA system, and it is desirable to apply the ef- fused gas from the outlet of adsorbing column to the purge gas for dehydration. Hence a target of our research is that the flow rate of purge gas for dehydration becomes equiva- lent to that of the effused gas from the outlet of adsorbing column. In the dehydrating operation by PSA, it was demon- strated that enough vapor removal capacity of purge gas against the removal amount of vapor spouted from the adsorbent is necessary especially in the primary period of dump removal to obtain high dehydration ratio, and the necessary rate is largely decreased after dump removal peri- od. Hence, some ideas for reducing necessary rate are essen- tial to realize practical PSA system. First idea to meet it is to increase the temperature of purge gas to some extent in ad- dition to the pressure swing especially in the primary period of dump removal, since vapor transfer capacity per unit purge gas volume increases at higher temperature. More- over, the moderate increase of temperature up to several dozen degrees effects on the enhancement of dehydration ratio since dehydration is an endoergic reaction. The diffu- sion rates are also expected to be increased by the moderate swing of temperature. Figure 9 shows the observed temper- ature dependency of the dehydration characteristics of the zeolite compared by the tritium removal amount, which shows that the rising of temperature improves the dehydra- tion ratio. Judging from the observations in Fig. 9, combina- tion of thermal swing up to several dozen degrees with PSA is confirmed as an effective method especially for the desir- 12000 10000 8000 6000 4000 2000 0 0 60 120 180 240 300 360 420 480 540 Elapsed time [min] Fig. 9 Effect of temperature on dehydration based on the ob- served dehydration ratio of tritiated water able quick dehydration with small gas whereas we recognize that it is contrary to the advantage of PSA to some extent. The oddly-shaped 80C curve especially in the primary period (0–60 min) shown in Fig. 9 is caused by the upper limitation of vapor transfer capacity of purge gas. Considering the above discussion as background, second and preferable idea that is not contrary to the advantage of PSA is the improvement of water dehydration characteristics of zeolite. Adjustment of SiO2 /Al2 O3 ratio of zeolite will become strong answer to achieve the compatibility of effec- tive dehydration with small gas. Our experimental results showed that larger SiO2 /Al2 O3 ratio leads the smaller acti- vated energy for dehydration (63.1 kJ/mol at SiO2 /Al2 O3 = 2.0, 47.7 kJ/mol at SiO2 /Al2 O3 =5.0). However it should be minded that modification of the SiO2 /Al2 O3 ratio for the improvement of dehydration characteristic has possibili- ty to prevent isotope separation function and adsorption capacity simultaneously. IV. Conclusion Application of pressure swing adsorption as the new detri- tiation process was investigated for processing a large amount of tritiated water produced in the future fusion power plant. Results of basic study on NaX zeolite, a candidate of adsorbent, concerning its isotope separation and dehydration characteristics were summarized as follows. (1) It was observed that NaX zeolite had clearly different break through time for H2O and HTO. Hence, it is certain that NaX zeolite can separate into the tritium concentrated water and the tritium reduced water by the difference of the break through time. (2) As for the pressure effect on the dehydration, it was verified that dehydration by decompression was clearly effective than that by diffusion. It was also demonstrated that enlargement of pressure difference between adsorb- ing and dehydrating operations was effective to obtain high dehydration ratio. (3) As for the effect of purge gas flow rate on the dehydra- tion, it was demonstrated that purge gas flow rate had a large influence on the dehydration ratio since enough vapor removal capacity of purge gas against the removal amount of vapor spouted from adsorbent was necessary to obtain high dehydration ratio. Acknowledgment The authors wish to express their sincere thanks to all staff members of the Tritium Engineering Laboratory of Japan Atomic Energy Research Institute for their great support. Drs. S. Matsuda, M. Seki, S. Seki and H. Takatsu are grate- fully appreciated for their continuous encouragement. References 1) R. V. Carlson, K. Okuno, Fusion Technol., 30, 900 (1996). 2) C. A. Gentile, J. L. Anderson, P. H. LaMarche, Fusion Tech- nol., 28, 1327 (1995). 3) P. D. Brennan, et al., Proc. 20th Symp. on Fusion Technology, Purge gas flow rate : 888 Ncm3/min Pressure in absorbing : 105.6 kPa Pressure in dehydrating : 37.3 kPa 27°C 60°C 40°C 80°C VOL. 42, NO. 6, JUNE 2005 Accumulated removal amount of tritium [Bq]PDF Image | Pressure Swing Adsorption to Water Detritiation Process

PDF Search Title:

Pressure Swing Adsorption to Water Detritiation ProcessOriginal File Name Searched:

PSA-Water-Detritiation-Process.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |