PDF Publication Title:

Text from PDF Page: 002

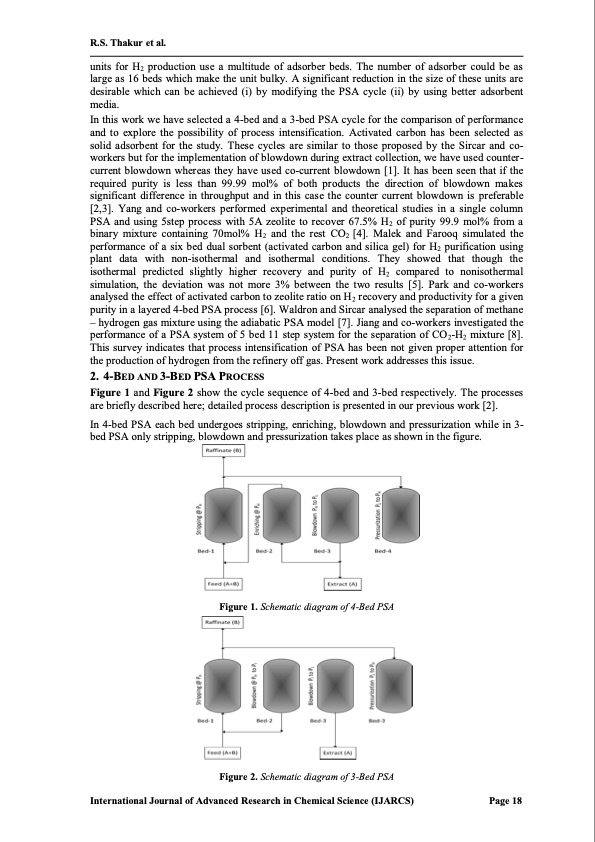

R.S. Thakur et al. units for H2 production use a multitude of adsorber beds. The number of adsorber could be as large as 16 beds which make the unit bulky. A significant reduction in the size of these units are desirable which can be achieved (i) by modifying the PSA cycle (ii) by using better adsorbent media. In this work we have selected a 4-bed and a 3-bed PSA cycle for the comparison of performance and to explore the possibility of process intensification. Activated carbon has been selected as solid adsorbent for the study. These cycles are similar to those proposed by the Sircar and co- workers but for the implementation of blowdown during extract collection, we have used counter- current blowdown whereas they have used co-current blowdown [1]. It has been seen that if the required purity is less than 99.99 mol% of both products the direction of blowdown makes significant difference in throughput and in this case the counter current blowdown is preferable [2,3]. Yang and co-workers performed experimental and theoretical studies in a single column PSA and using 5step process with 5A zeolite to recover 67.5% H2 of purity 99.9 mol% from a binary mixture containing 70mol% H2 and the rest CO2 [4]. Malek and Farooq simulated the performance of a six bed dual sorbent (activated carbon and silica gel) for H2 purification using plant data with non-isothermal and isothermal conditions. They showed that though the isothermal predicted slightly higher recovery and purity of H2 compared to nonisothermal simulation, the deviation was not more 3% between the two results [5]. Park and co-workers analysed the effect of activated carbon to zeolite ratio on H2 recovery and productivity for a given purity in a layered 4-bed PSA process [6]. Waldron and Sircar analysed the separation of methane – hydrogen gas mixture using the adiabatic PSA model [7]. Jiang and co-workers investigated the performance of a PSA system of 5 bed 11 step system for the separation of CO2-H2 mixture [8]. This survey indicates that process intensification of PSA has been not given proper attention for the production of hydrogen from the refinery off gas. Present work addresses this issue. 2. 4-BED AND 3-BED PSA PROCESS Figure 1 and Figure 2 show the cycle sequence of 4-bed and 3-bed respectively. The processes are briefly described here; detailed process description is presented in our previous work [2]. In 4-bed PSA each bed undergoes stripping, enriching, blowdown and pressurization while in 3- bed PSA only stripping, blowdown and pressurization takes place as shown in the figure. Figure 1. Schematic diagram of 4-Bed PSA Figure 2. Schematic diagram of 3-Bed PSA International Journal of Advanced Research in Chemical Science (IJARCS) Page 18PDF Image | Separation of CO2 H2 Gas Mixture Using PSA

PDF Search Title:

Separation of CO2 H2 Gas Mixture Using PSAOriginal File Name Searched:

pressure-swing-adsorption-process.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |