PDF Publication Title:

Text from PDF Page: 003

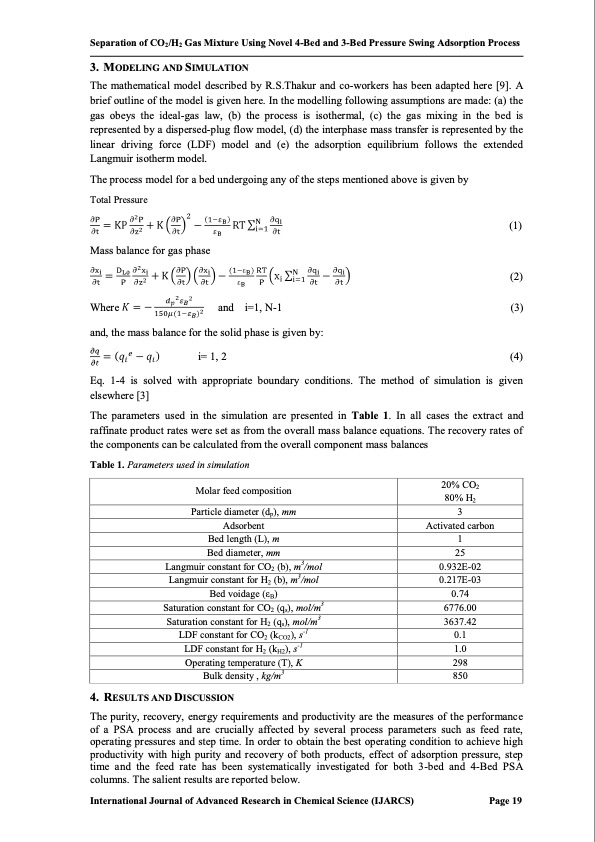

Separation of CO2/H2 Gas Mixture Using Novel 4-Bed and 3-Bed Pressure Swing Adsorption Process 3. MODELING AND SIMULATION The mathematical model described by R.S.Thakur and co-workers has been adapted here [9]. A brief outline of the model is given here. In the modelling following assumptions are made: (a) the gas obeys the ideal-gas law, (b) the process is isothermal, (c) the gas mixing in the bed is represented by a dispersed-plug flow model, (d) the interphase mass transfer is represented by the linear driving force (LDF) model and (e) the adsorption equilibrium follows the extended Langmuir isotherm model. The process model for a bed undergoing any of the steps mentioned above is given by Total Pressure Mass balance for gas phase (1) (2) Where and i=1, N-1 (3) and, the mass balance for the solid phase is given by: i= 1, 2 (4) Eq. 1-4 is solved with appropriate boundary conditions. The method of simulation is given elsewhere [3] The parameters used in the simulation are presented in Table 1. In all cases the extract and raffinate product rates were set as from the overall mass balance equations. The recovery rates of the components can be calculated from the overall component mass balances Table 1. Parameters used in simulation Molar feed composition Particle diameter (dp), mm Adsorbent Bed length (L), m Bed diameter, mm Langmuir constant for CO2 (b), m3/mol Langmuir constant for H2 (b), m3/mol Bed voidage (εB) Saturation constant for CO2 (qs), mol/m3 Saturation constant for H2 (qs), mol/m3 LDF constant for CO2 (kCO2), s-1 LDF constant for H2 (kH2), s-1 Operating temperature (T), K Bulk density , kg/m3 4. RESULTS AND DISCUSSION 20% CO2 80% H2 3 Activated carbon 1 25 0.932E-02 0.217E-03 0.74 6776.00 3637.42 0.1 1.0 298 850 The purity, recovery, energy requirements and productivity are the measures of the performance of a PSA process and are crucially affected by several process parameters such as feed rate, operating pressures and step time. In order to obtain the best operating condition to achieve high productivity with high purity and recovery of both products, effect of adsorption pressure, step time and the feed rate has been systematically investigated for both 3-bed and 4-Bed PSA columns. The salient results are reported below. International Journal of Advanced Research in Chemical Science (IJARCS) Page 19PDF Image | Separation of CO2 H2 Gas Mixture Using PSA

PDF Search Title:

Separation of CO2 H2 Gas Mixture Using PSAOriginal File Name Searched:

pressure-swing-adsorption-process.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |