PDF Publication Title:

Text from PDF Page: 007

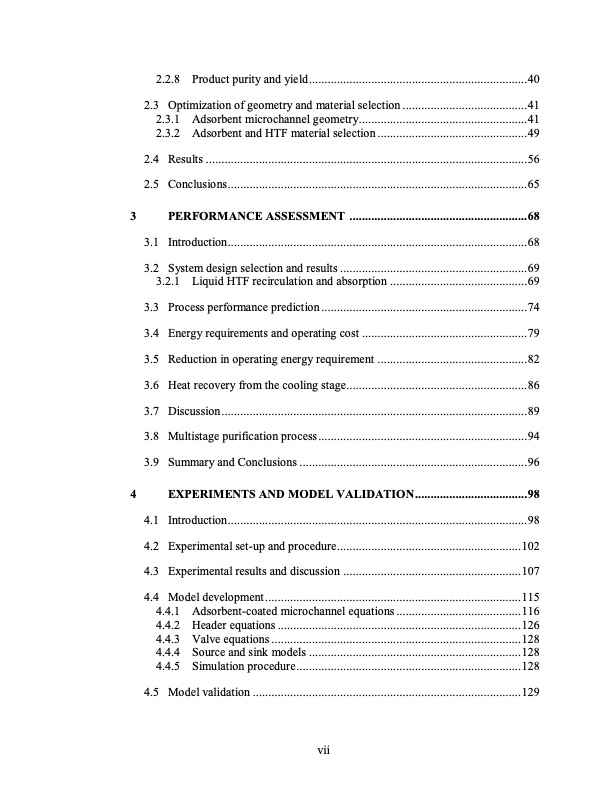

2.2.8 Product purity and yield......................................................................40 2.3 Optimization of geometry and material selection ........................................41 2.3.1 Adsorbent microchannel geometry......................................................41 2.3.2 Adsorbent and HTF material selection ................................................49 2.4 2.5 3 3.1 Results .......................................................................................................56 Conclusions................................................................................................65 PERFORMANCE ASSESSMENT .........................................................68 Introduction................................................................................................68 3.3 3.4 3.5 3.6 3.7 3.8 3.9 4 4.1 4.2 4.3 Process performance prediction ..................................................................74 Energy requirements and operating cost .....................................................79 Reduction in operating energy requirement ................................................82 Heat recovery from the cooling stage..........................................................86 Discussion..................................................................................................89 Multistage purification process...................................................................94 Summary and Conclusions .........................................................................96 EXPERIMENTS AND MODEL VALIDATION....................................98 Introduction................................................................................................98 Experimental set-up and procedure...........................................................102 Experimental results and discussion .........................................................107 System design selection and results ............................................................69 3.2 3.2.1 Liquid HTF recirculation and absorption ............................................69 4.4 4.4.1 Adsorbent-coated microchannel equations ........................................116 4.4.2 Header equations ..............................................................................126 4.4.3 Valve equations ................................................................................128 4.4.4 Source and sink models ....................................................................128 4.4.5 Simulation procedure........................................................................128 4.5 Model validation ......................................................................................129 Model development ..................................................................................115 viiPDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |