PDF Publication Title:

Text from PDF Page: 049

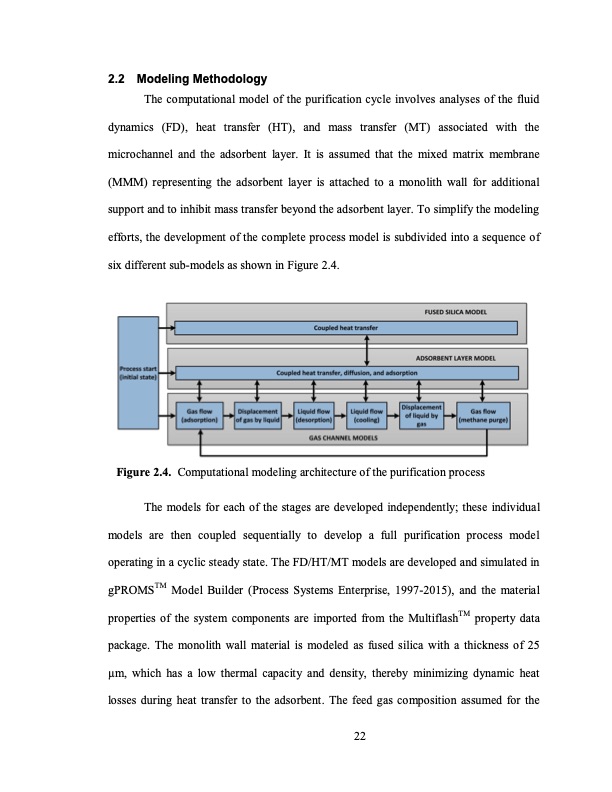

2.2 Modeling Methodology The computational model of the purification cycle involves analyses of the fluid dynamics (FD), heat transfer (HT), and mass transfer (MT) associated with the microchannel and the adsorbent layer. It is assumed that the mixed matrix membrane (MMM) representing the adsorbent layer is attached to a monolith wall for additional support and to inhibit mass transfer beyond the adsorbent layer. To simplify the modeling efforts, the development of the complete process model is subdivided into a sequence of six different sub-models as shown in Figure 2.4. Figure 2.4. Computational modeling architecture of the purification process The models for each of the stages are developed independently; these individual models are then coupled sequentially to develop a full purification process model operating in a cyclic steady state. The FD/HT/MT models are developed and simulated in gPROMSTM Model Builder (Process Systems Enterprise, 1997-2015), and the material properties of the system components are imported from the MultiflashTM property data package. The monolith wall material is modeled as fused silica with a thickness of 25 μm, which has a low thermal capacity and density, thereby minimizing dynamic heat losses during heat transfer to the adsorbent. The feed gas composition assumed for the 22PDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |