PDF Publication Title:

Text from PDF Page: 102

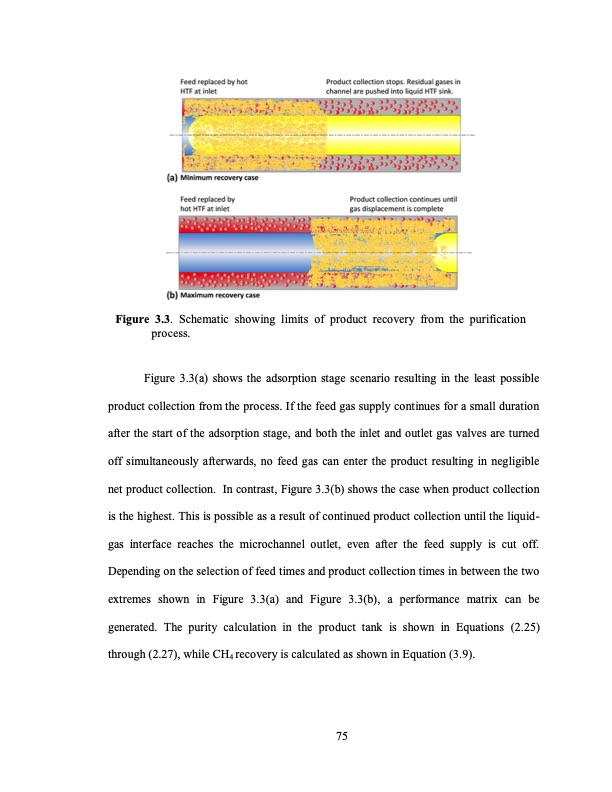

Figure 3.3. Schematic showing limits of product recovery from the purification process. Figure 3.3(a) shows the adsorption stage scenario resulting in the least possible product collection from the process. If the feed gas supply continues for a small duration after the start of the adsorption stage, and both the inlet and outlet gas valves are turned off simultaneously afterwards, no feed gas can enter the product resulting in negligible net product collection. In contrast, Figure 3.3(b) shows the case when product collection is the highest. This is possible as a result of continued product collection until the liquid- gas interface reaches the microchannel outlet, even after the feed supply is cut off. Depending on the selection of feed times and product collection times in between the two extremes shown in Figure 3.3(a) and Figure 3.3(b), a performance matrix can be generated. The purity calculation in the product tank is shown in Equations (2.25) through (2.27), while CH4 recovery is calculated as shown in Equation (3.9). 75PDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |