PDF Publication Title:

Text from PDF Page: 006

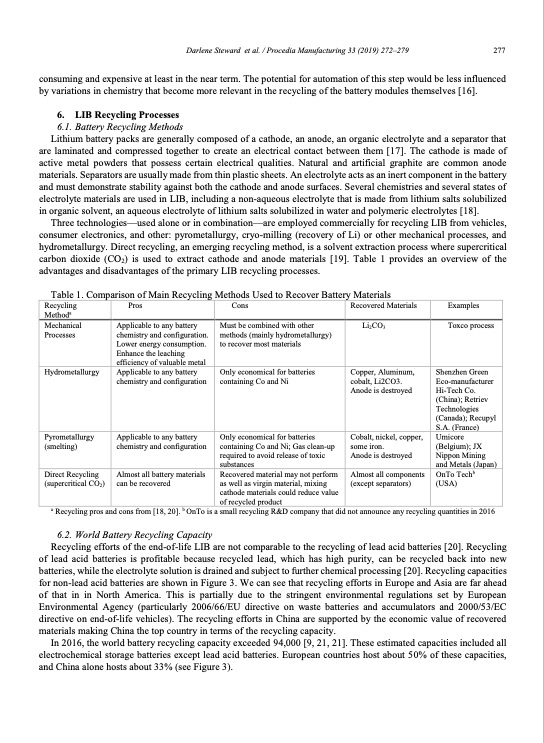

Darlene Steward et al. / Procedia Manufacturing 33 (2019) 272–279 277 6 Steward et al./ Procedia Manufacturing 00 (2018) 000–000 consuming and expensive at least in the near term. The potential for automation of this step would be less influenced by variations in chemistry that become more relevant in the recycling of the battery modules themselves [16]. 6. LIB Recycling Processes 6.1. Battery Recycling Methods Lithium battery packs are generally composed of a cathode, an anode, an organic electrolyte and a separator that are laminated and compressed together to create an electrical contact between them [17]. The cathode is made of active metal powders that possess certain electrical qualities. Natural and artificial graphite are common anode materials. Separators are usually made from thin plastic sheets. An electrolyte acts as an inert component in the battery and must demonstrate stability against both the cathode and anode surfaces. Several chemistries and several states of electrolyte materials are used in LIB, including a non-aqueous electrolyte that is made from lithium salts solubilized in organic solvent, an aqueous electrolyte of lithium salts solubilized in water and polymeric electrolytes [18]. Three technologies—used alone or in combination—are employed commercially for recycling LIB from vehicles, consumer electronics, and other: pyrometallurgy, cryo-milling (recovery of Li) or other mechanical processes, and hydrometallurgy. Direct recycling, an emerging recycling method, is a solvent extraction process where supercritical carbon dioxide (CO2) is used to extract cathode and anode materials [19]. Table 1 provides an overview of the advantages and disadvantages of the primary LIB recycling processes. Table 1. Comparison of Main Recycling Methods Used to Recover Battery Materials Recycling Methoda Pros Cons Recovered Materials Examples Mechanical Processes Applicable to any battery chemistry and configuration. Lower energy consumption. Enhance the leaching efficiency of valuable metal Must be combined with other methods (mainly hydrometallurgy) to recover most materials Li2CO3 Toxco process Hydrometallurgy Applicable to any battery chemistry and configuration Only economical for batteries containing Co and Ni Copper, Aluminum, cobalt, Li2CO3. Anode is destroyed Shenzhen Green Eco-manufacturer Hi-Tech Co. (China); Retriev Technologies (Canada); Recupyl S.A. (France) Pyrometallurgy (smelting) Direct Recycling (supercritical CO2) Applicable to any battery Only economical for batteries chemistry and configuration containing Co and Ni; Gas clean-up required to avoid release of toxic substances Almost all battery materials Recovered material may not perform can be recovered as well as virgin material, mixing cathode materials could reduce value Cobalt, nickel, copper, some iron. Anode is destroyed Almost all components (except separators) Umicore (Belgium); JX Nippon Mining and Metals (Japan) OnTo Techb (USA) of recycled product a Recycling pros and cons from [18, 20]. b OnTo is a small recycling R&D company that did not announce any recycling quantities in 2016 6.2. World Battery Recycling Capacity Recycling efforts of the end-of-life LIB are not comparable to the recycling of lead acid batteries [20]. Recycling of lead acid batteries is profitable because recycled lead, which has high purity, can be recycled back into new batteries, while the electrolyte solution is drained and subject to further chemical processing [20]. Recycling capacities for non-lead acid batteries are shown in Figure 3. We can see that recycling efforts in Europe and Asia are far ahead of that in in North America. This is partially due to the stringent environmental regulations set by European Environmental Agency (particularly 2006/66/EU directive on waste batteries and accumulators and 2000/53/EC directive on end-of-life vehicles). The recycling efforts in China are supported by the economic value of recovered materials making China the top country in terms of the recycling capacity. In 2016, the world battery recycling capacity exceeded 94,000 [9, 21, 21]. These estimated capacities included all electrochemical storage batteries except lead acid batteries. European countries host about 50% of these capacities, and China alone hosts about 33% (see Figure 3).PDF Image | Li-ion battery recycling challenges

PDF Search Title:

Li-ion battery recycling challengesOriginal File Name Searched:

71350.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |