PDF Publication Title:

Text from PDF Page: 012

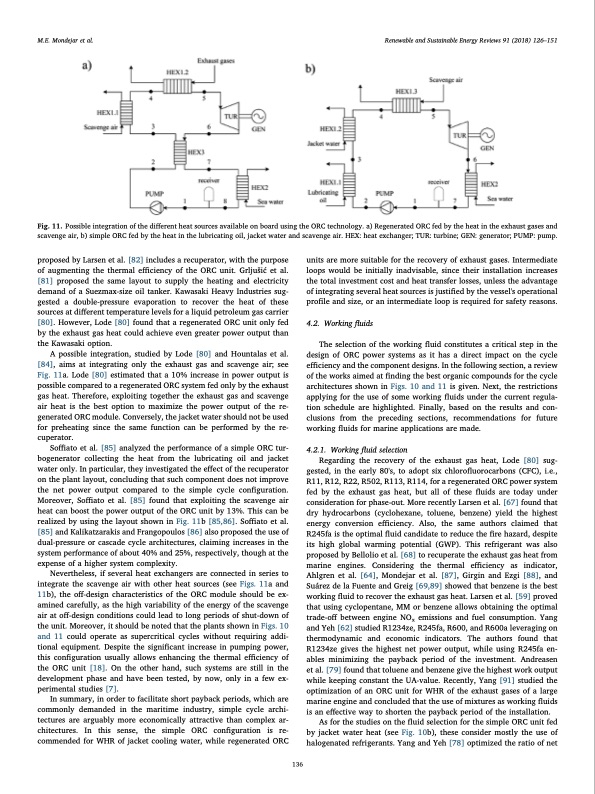

M.E. Mondejar et al. Renewable and Sustainable Energy Reviews 91 (2018) 126–151 Fig. 11. Possible integration of the different heat sources available on board using the ORC technology. a) Regenerated ORC fed by the heat in the exhaust gases and scavenge air, b) simple ORC fed by the heat in the lubricating oil, jacket water and scavenge air. HEX: heat exchanger; TUR: turbine; GEN: generator; PUMP: pump. proposed by Larsen et al. [82] includes a recuperator, with the purpose of augmenting the thermal efficiency of the ORC unit. Grljušić et al. [81] proposed the same layout to supply the heating and electricity demand of a Suezmax-size oil tanker. Kawasaki Heavy Industries sug- gested a double-pressure evaporation to recover the heat of these sources at different temperature levels for a liquid petroleum gas carrier [80]. However, Lode [80] found that a regenerated ORC unit only fed by the exhaust gas heat could achieve even greater power output than the Kawasaki option. A possible integration, studied by Lode [80] and Hountalas et al. [84], aims at integrating only the exhaust gas and scavenge air; see Fig. 11a. Lode [80] estimated that a 10% increase in power output is possible compared to a regenerated ORC system fed only by the exhaust gas heat. Therefore, exploiting together the exhaust gas and scavenge air heat is the best option to maximize the power output of the re- generated ORC module. Conversely, the jacket water should not be used for preheating since the same function can be performed by the re- cuperator. Soffiato et al. [85] analyzed the performance of a simple ORC tur- bogenerator collecting the heat from the lubricating oil and jacket water only. In particular, they investigated the effect of the recuperator on the plant layout, concluding that such component does not improve the net power output compared to the simple cycle configuration. Moreover, Soffiato et al. [85] found that exploiting the scavenge air heat can boost the power output of the ORC unit by 13%. This can be realized by using the layout shown in Fig. 11b [85,86]. Soffiato et al. [85] and Kalikatzarakis and Frangopoulos [86] also proposed the use of dual-pressure or cascade cycle architectures, claiming increases in the system performance of about 40% and 25%, respectively, though at the expense of a higher system complexity. Nevertheless, if several heat exchangers are connected in series to integrate the scavenge air with other heat sources (see Figs. 11a and 11b), the off-design characteristics of the ORC module should be ex- amined carefully, as the high variability of the energy of the scavenge air at off-design conditions could lead to long periods of shut-down of the unit. Moreover, it should be noted that the plants shown in Figs. 10 and 11 could operate as supercritical cycles without requiring addi- tional equipment. Despite the significant increase in pumping power, this configuration usually allows enhancing the thermal efficiency of the ORC unit [18]. On the other hand, such systems are still in the development phase and have been tested, by now, only in a few ex- perimental studies [7]. In summary, in order to facilitate short payback periods, which are commonly demanded in the maritime industry, simple cycle archi- tectures are arguably more economically attractive than complex ar- chitectures. In this sense, the simple ORC configuration is re- commended for WHR of jacket cooling water, while regenerated ORC units are more suitable for the recovery of exhaust gases. Intermediate loops would be initially inadvisable, since their installation increases the total investment cost and heat transfer losses, unless the advantage of integrating several heat sources is justified by the vessel's operational profile and size, or an intermediate loop is required for safety reasons. 4.2. Working fluids The selection of the working fluid constitutes a critical step in the design of ORC power systems as it has a direct impact on the cycle efficiency and the component designs. In the following section, a review of the works aimed at finding the best organic compounds for the cycle architectures shown in Figs. 10 and 11 is given. Next, the restrictions applying for the use of some working fluids under the current regula- tion schedule are highlighted. Finally, based on the results and con- clusions from the preceding sections, recommendations for future working fluids for marine applications are made. 4.2.1. Working fluid selection Regarding the recovery of the exhaust gas heat, Lode [80] sug- gested, in the early 80's, to adopt six chlorofluorocarbons (CFC), i.e., R11, R12, R22, R502, R113, R114, for a regenerated ORC power system fed by the exhaust gas heat, but all of these fluids are today under consideration for phase-out. More recently Larsen et al. [67] found that dry hydrocarbons (cyclohexane, toluene, benzene) yield the highest energy conversion efficiency. Also, the same authors claimed that R245fa is the optimal fluid candidate to reduce the fire hazard, despite its high global warming potential (GWP). This refrigerant was also proposed by Bellolio et al. [68] to recuperate the exhaust gas heat from marine engines. Considering the thermal efficiency as indicator, Ahlgren et al. [64], Mondejar et al. [87], Girgin and Ezgi [88], and Suárez de la Fuente and Greig [69,89] showed that benzene is the best working fluid to recover the exhaust gas heat. Larsen et al. [59] proved that using cyclopentane, MM or benzene allows obtaining the optimal trade-off between engine NOx emissions and fuel consumption. Yang and Yeh [62] studied R1234ze, R245fa, R600, and R600a leveraging on thermodynamic and economic indicators. The authors found that R1234ze gives the highest net power output, while using R245fa en- ables minimizing the payback period of the investment. Andreasen et al. [79] found that toluene and benzene give the highest work output while keeping constant the UA-value. Recently, Yang [91] studied the optimization of an ORC unit for WHR of the exhaust gases of a large marine engine and concluded that the use of mixtures as working fluids is an effective way to shorten the payback period of the installation. As for the studies on the fluid selection for the simple ORC unit fed by jacket water heat (see Fig. 10b), these consider mostly the use of halogenated refrigerants. Yang and Yeh [78] optimized the ratio of net 136PDF Image | organic Rankine cycle power systems for maritime applications

PDF Search Title:

organic Rankine cycle power systems for maritime applicationsOriginal File Name Searched:

1_s20_S136403211830162X_main.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |