PDF Publication Title:

Text from PDF Page: 009

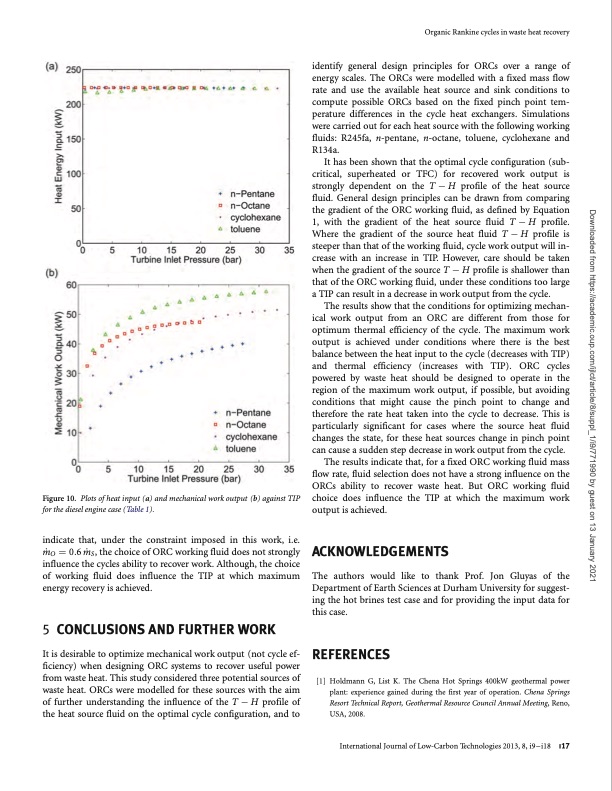

Figure 10. Plots of heat input (a) and mechanical work output (b) against TIP for the diesel engine case (Table 1). indicate that, under the constraint imposed in this work, i.e. m_ O 1⁄4 0:6 m_ S, the choice of ORC working fluid does not strongly influence the cycles ability to recover work. Although, the choice of working fluid does influence the TIP at which maximum energy recovery is achieved. 5 CONCLUSIONS AND FURTHER WORK It is desirable to optimize mechanical work output (not cycle ef- ficiency) when designing ORC systems to recover useful power from waste heat. This study considered three potential sources of waste heat. ORCs were modelled for these sources with the aim of further understanding the influence of the T H profile of the heat source fluid on the optimal cycle configuration, and to identify general design principles for ORCs over a range of energy scales. The ORCs were modelled with a fixed mass flow rate and use the available heat source and sink conditions to compute possible ORCs based on the fixed pinch point tem- perature differences in the cycle heat exchangers. Simulations were carried out for each heat source with the following working fluids: R245fa, n-pentane, n-octane, toluene, cyclohexane and R134a. It has been shown that the optimal cycle configuration (sub- critical, superheated or TFC) for recovered work output is strongly dependent on the T H profile of the heat source fluid. General design principles can be drawn from comparing the gradient of the ORC working fluid, as defined by Equation 1, with the gradient of the heat source fluid T H profile. Where the gradient of the source heat fluid T H profile is steeper than that of the working fluid, cycle work output will in- crease with an increase in TIP. However, care should be taken when the gradient of the source T H profile is shallower than that of the ORC working fluid, under these conditions too large a TIP can result in a decrease in work output from the cycle. The results show that the conditions for optimizing mechan- ical work output from an ORC are different from those for optimum thermal efficiency of the cycle. The maximum work output is achieved under conditions where there is the best balance between the heat input to the cycle (decreases with TIP) and thermal efficiency (increases with TIP). ORC cycles powered by waste heat should be designed to operate in the region of the maximum work output, if possible, but avoiding conditions that might cause the pinch point to change and therefore the rate heat taken into the cycle to decrease. This is particularly significant for cases where the source heat fluid changes the state, for these heat sources change in pinch point can cause a sudden step decrease in work output from the cycle. The results indicate that, for a fixed ORC working fluid mass flow rate, fluid selection does not have a strong influence on the ORCs ability to recover waste heat. But ORC working fluid choice does influence the TIP at which the maximum work output is achieved. ACKNOWLEDGEMENTS The authors would like to thank Prof. Jon Gluyas of the Department of Earth Sciences at Durham University for suggest- ing the hot brines test case and for providing the input data for this case. REFERENCES [1] Holdmann G, List K. The Chena Hot Springs 400kW geothermal power plant: experience gained during the first year of operation. Chena Springs Resort Technical Report, Geothermal Resource Council Annual Meeting, Reno, USA, 2008. Organic Rankine cycles in waste heat recovery International Journal of Low-Carbon Technologies 2013, 8, i9–i18 i17 Downloaded from https://academic.oup.com/ijlct/article/8/suppl_1/i9/771990 by guest on 13 January 2021PDF Image | Organic Rankine cycles in waste heat recovery

PDF Search Title:

Organic Rankine cycles in waste heat recoveryOriginal File Name Searched:

ctt033.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |