PDF Publication Title:

Text from PDF Page: 010

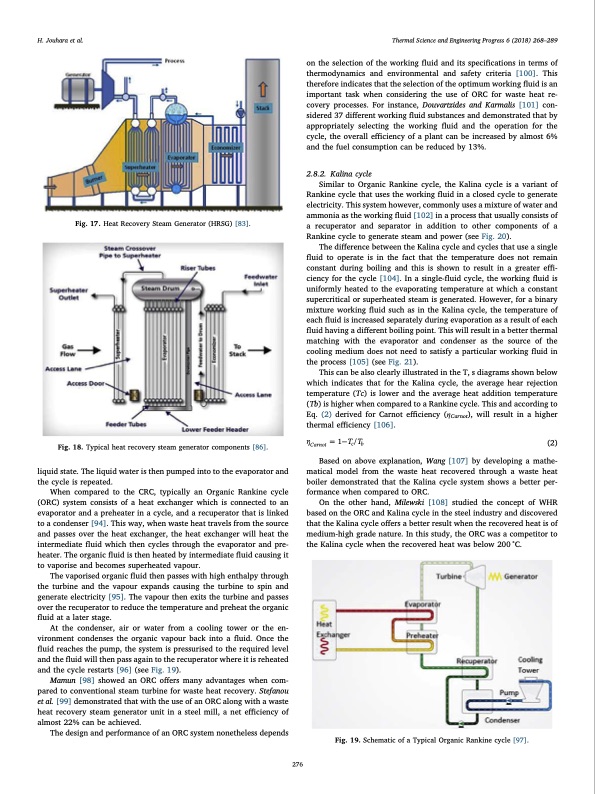

H. Jouhara et al. Thermal Science and Engineering Progress 6 (2018) 268–289 Fig. 17. Heat Recovery Steam Generator (HRSG) [83]. Fig. 18. Typical heat recovery steam generator components [86]. liquid state. The liquid water is then pumped into to the evaporator and the cycle is repeated. When compared to the CRC, typically an Organic Rankine cycle (ORC) system consists of a heat exchanger which is connected to an evaporator and a preheater in a cycle, and a recuperator that is linked to a condenser [94]. This way, when waste heat travels from the source and passes over the heat exchanger, the heat exchanger will heat the intermediate fluid which then cycles through the evaporator and pre- heater. The organic fluid is then heated by intermediate fluid causing it to vaporise and becomes superheated vapour. The vaporised organic fluid then passes with high enthalpy through the turbine and the vapour expands causing the turbine to spin and generate electricity [95]. The vapour then exits the turbine and passes over the recuperator to reduce the temperature and preheat the organic fluid at a later stage. At the condenser, air or water from a cooling tower or the en- vironment condenses the organic vapour back into a fluid. Once the fluid reaches the pump, the system is pressurised to the required level and the fluid will then pass again to the recuperator where it is reheated and the cycle restarts [96] (see Fig. 19). Mamun [98] showed an ORC offers many advantages when com- pared to conventional steam turbine for waste heat recovery. Stefanou et al. [99] demonstrated that with the use of an ORC along with a waste heat recovery steam generator unit in a steel mill, a net efficiency of almost 22% can be achieved. The design and performance of an ORC system nonetheless depends on the selection of the working fluid and its specifications in terms of thermodynamics and environmental and safety criteria [100]. This therefore indicates that the selection of the optimum working fluid is an important task when considering the use of ORC for waste heat re- covery processes. For instance, Douvartzides and Karmalis [101] con- sidered 37 different working fluid substances and demonstrated that by appropriately selecting the working fluid and the operation for the cycle, the overall efficiency of a plant can be increased by almost 6% and the fuel consumption can be reduced by 13%. 2.8.2. Kalina cycle Similar to Organic Rankine cycle, the Kalina cycle is a variant of Rankine cycle that uses the working fluid in a closed cycle to generate electricity. This system however, commonly uses a mixture of water and ammonia as the working fluid [102] in a process that usually consists of a recuperator and separator in addition to other components of a Rankine cycle to generate steam and power (see Fig. 20). The difference between the Kalina cycle and cycles that use a single fluid to operate is in the fact that the temperature does not remain constant during boiling and this is shown to result in a greater effi- ciency for the cycle [104]. In a single-fluid cycle, the working fluid is uniformly heated to the evaporating temperature at which a constant supercritical or superheated steam is generated. However, for a binary mixture working fluid such as in the Kalina cycle, the temperature of each fluid is increased separately during evaporation as a result of each fluid having a different boiling point. This will result in a better thermal matching with the evaporator and condenser as the source of the cooling medium does not need to satisfy a particular working fluid in the process [105] (see Fig. 21). This can be also clearly illustrated in the T, s diagrams shown below which indicates that for the Kalina cycle, the average hear rejection temperature (Tc) is lower and the average heat addition temperature (Tb) is higher when compared to a Rankine cycle. This and according to Eq. (2) derived for Carnot efficiency (ηCarnot), will result in a higher thermal efficiency [106]. η = 1−T /T (2) Carnot c b Based on above explanation, Wang [107] by developing a mathe- matical model from the waste heat recovered through a waste heat boiler demonstrated that the Kalina cycle system shows a better per- formance when compared to ORC. On the other hand, Milewski [108] studied the concept of WHR based on the ORC and Kalina cycle in the steel industry and discovered that the Kalina cycle offers a better result when the recovered heat is of medium-high grade nature. In this study, the ORC was a competitor to the Kalina cycle when the recovered heat was below 200 °C. 276 Fig. 19. Schematic of a Typical Organic Rankine cycle [97].PDF Image | Waste Heat Recovery Technologies and Applications

PDF Search Title:

Waste Heat Recovery Technologies and ApplicationsOriginal File Name Searched:

1-s20-S2451904918300015-main.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |