PDF Publication Title:

Text from PDF Page: 002

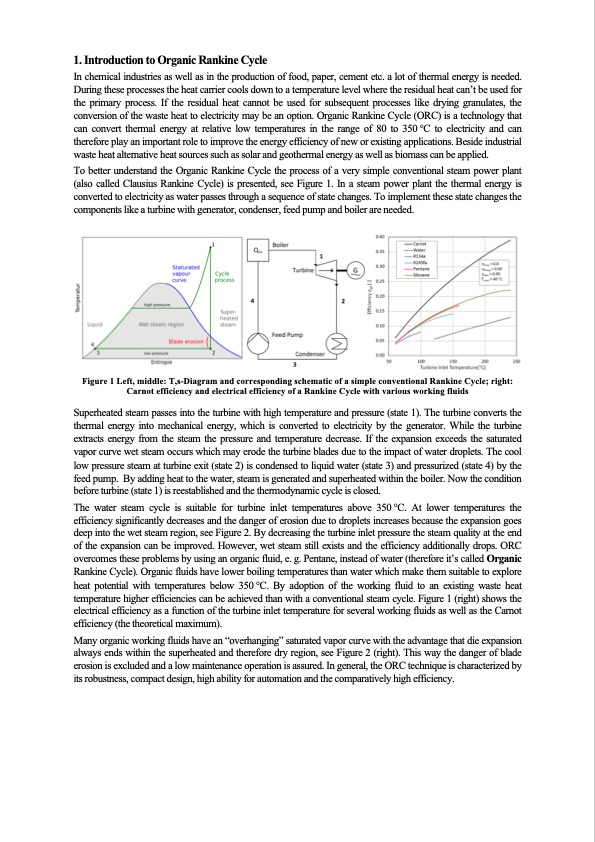

1. Introduction to Organic Rankine Cycle In chemical industries as well as in the production of food, paper, cement etc. a lot of thermal energy is needed. During these processes the heat carrier cools down to a temperature level where the residual heat can’t be used for the primary process. If the residual heat cannot be used for subsequent processes like drying granulates, the conversion of the waste heat to electricity may be an option. Organic Rankine Cycle (ORC) is a technology that can convert thermal energy at relative low temperatures in the range of 80 to 350 °C to electricity and can therefore play an important role to improve the energy efficiency of new or existing applications. Beside industrial waste heat alternative heat sources such as solar and geothermal energy as well as biomass can be applied. To better understand the Organic Rankine Cycle the process of a very simple conventional steam power plant (also called Clausius Rankine Cycle) is presented, see Figure 1. In a steam power plant the thermal energy is converted to electricity as water passes through a sequence of state changes. To implement these state changes the components like a turbine with generator, condenser, feed pump and boiler are needed. Figure 1 Left, middle: T,s-Diagram and corresponding schematic of a simple conventional Rankine Cycle; right: Carnot efficiency and electrical efficiency of a Rankine Cycle with various working fluids Superheated steam passes into the turbine with high temperature and pressure (state 1). The turbine converts the thermal energy into mechanical energy, which is converted to electricity by the generator. While the turbine extracts energy from the steam the pressure and temperature decrease. If the expansion exceeds the saturated vapor curve wet steam occurs which may erode the turbine blades due to the impact of water droplets. The cool low pressure steam at turbine exit (state 2) is condensed to liquid water (state 3) and pressurized (state 4) by the feed pump. By adding heat to the water, steam is generated and superheated within the boiler. Now the condition before turbine (state 1) is reestablished and the thermodynamic cycle is closed. The water steam cycle is suitable for turbine inlet temperatures above 350 °C. At lower temperatures the efficiency significantly decreases and the danger of erosion due to droplets increases because the expansion goes deep into the wet steam region, see Figure 2. By decreasing the turbine inlet pressure the steam quality at the end of the expansion can be improved. However, wet steam still exists and the efficiency additionally drops. ORC overcomes these problems by using an organic fluid, e. g. Pentane, instead of water (therefore it’s called Organic Rankine Cycle). Organic fluids have lower boiling temperatures than water which make them suitable to explore heat potential with temperatures below 350 °C. By adoption of the working fluid to an existing waste heat temperature higher efficiencies can be achieved than with a conventional steam cycle. Figure 1 (right) shows the electrical efficiency as a function of the turbine inlet temperature for several working fluids as well as the Carnot efficiency (the theoretical maximum). Many organic working fluids have an “overhanging” saturated vapor curve with the advantage that die expansion always ends within the superheated and therefore dry region, see Figure 2 (right). This way the danger of blade erosion is excluded and a low maintenance operation is assured. In general, the ORC technique is characterized by its robustness, compact design, high ability for automation and the comparatively high efficiency.PDF Image | Application of Organic Rankine Cycles (ORC)

PDF Search Title:

Application of Organic Rankine Cycles (ORC)Original File Name Searched:

orc-final-paper-wec2011-2011-07-30.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |