PDF Publication Title:

Text from PDF Page: 007

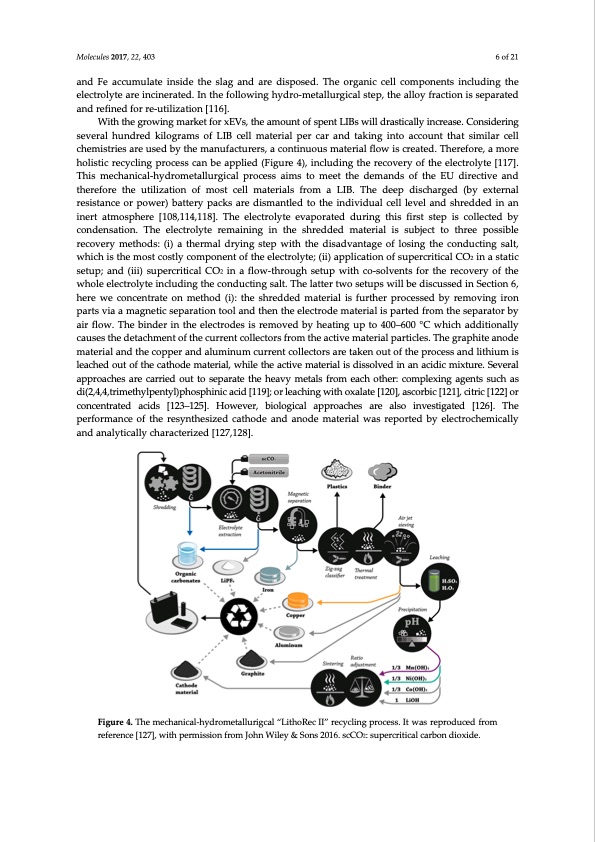

Molecules 2017, 22, 403 6 of 21 and Fe accumulate inside the slag and are disposed. The organic cell components including the electrolyte are incinerated. In the following hydro-metallurgical step, the alloy fraction is separated and refined for re-utilization [116]. With the growing market for xEVs, the amount of spent LIBs will drastically increase. Considering several hundred kilograms of LIB cell material per car and taking into account that similar cell chemistries are used by the manufacturers, a continuous material flow is created. Therefore, a more holistic recycling process can be applied (Figure 4), including the recovery of the electrolyte [117]. This mechanical-hydrometallurgical process aims to meet the demands of the EU directive and therefore the utilization of most cell materials from a LIB. The deep discharged (by external resistance or power) battery packs are dismantled to the individual cell level and shredded in an inert atmosphere [108,114,118]. The electrolyte evaporated during this first step is collected by condensation. The electrolyte remaining in the shredded material is subject to three possible recovery methods: (i) a thermal drying step with the disadvantage of losing the conducting salt, which is the most costly component of the electrolyte; (ii) application of supercritical CO2 in a static setup; and (iii) supercritical CO2 in a flow-through setup with co-solvents for the recovery of the whole electrolyte including the conducting salt. The latter two setups will be discussed in Section 6, here we concentrate on method (i): the shredded material is further processed by removing iron parts via a magnetic separation tool and then the electrode material is parted from the separator by air flow. The binder in the electrodes is removed by heating up to 400–600 °C which additionally causes the detachment of the current collectors from the active material particles. The graphite anode material and the copper and aluminum current collectors are taken out of the process and lithium is leached out of the cathode material, while the active material is dissolved in an acidic mixture. Several approaches are carried out to separate the heavy metals from each other: complexing agents such as di(2,4,4,trimethylpentyl)phosphinic acid [119]; or leaching with oxalate [120], ascorbic [121], citric [122] or concentrated acids [123–125]. However, biological approaches are also investigated [126]. The performance of the resynthesized cathode and anode material was reported by electrochemically and analytically characterized [127,128]. Figure 4. The mechanical-hydrometallurigcal “LithoRec II” recycling process. It was reproduced from reference [127], with permission from John Wiley & Sons 2016. scCO2: supercritical carbon dioxide.PDF Image | CO2 for Recycling and Sample Preparation of Lithium Ion Battery

PDF Search Title:

CO2 for Recycling and Sample Preparation of Lithium Ion BatteryOriginal File Name Searched:

molecules-22-00403.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |