PDF Publication Title:

Text from PDF Page: 003

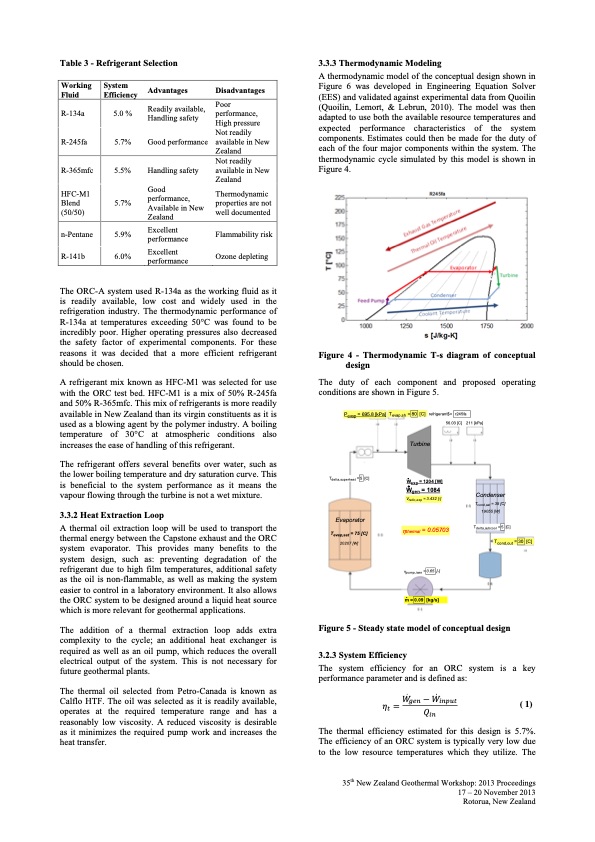

Table 3 - Refrigerant Selection 3.3.3 Thermodynamic Modeling A thermodynamic model of the conceptual design shown in Figure 6 was developed in Engineering Equation Solver (EES) and validated against experimental data from Quoilin (Quoilin, Lemort, & Lebrun, 2010). The model was then adapted to use both the available resource temperatures and expected performance characteristics of the system components. Estimates could then be made for the duty of each of the four major components within the system. The thermodynamic cycle simulated by this model is shown in Figure 4. Working System Fluid Efficiency R-134a 5.0 % R-245fa 5.7% R-365mfc 5.5% HFC-M1 Blend 5.7% (50/50) n-Pentane 5.9% R-141b 6.0% Advantages Readily available, Handling safety Good performance Handling safety Good performance, Available in New Zealand Excellent performance Excellent performance Disadvantages Poor performance, High pressure Not readily available in New Zealand Not readily available in New Zealand Thermodynamic properties are not well documented Flammability risk Ozone depleting The ORC-A system used R-134a as the working fluid as it is readily available, low cost and widely used in the refrigeration industry. The thermodynamic performance of R-134a at temperatures exceeding 50°C was found to be incredibly poor. Higher operating pressures also decreased the safety factor of experimental components. For these reasons it was decided that a more efficient refrigerant should be chosen. A refrigerant mix known as HFC-M1 was selected for use with the ORC test bed. HFC-M1 is a mix of 50% R-245fa and 50% R-365mfc. This mix of refrigerants is more readily available in New Zealand than its virgin constituents as it is used as a blowing agent by the polymer industry. A boiling temperature of 30°C at atmospheric conditions also increases the ease of handling of this refrigerant. The refrigerant offers several benefits over water, such as the lower boiling temperature and dry saturation curve. This is beneficial to the system performance as it means the vapour flowing through the turbine is not a wet mixture. 3.3.2 Heat Extraction Loop A thermal oil extraction loop will be used to transport the thermal energy between the Capstone exhaust and the ORC system evaporator. This provides many benefits to the system design, such as: preventing degradation of the refrigerant due to high film temperatures, additional safety as the oil is non-flammable, as well as making the system easier to control in a laboratory environment. It also allows the ORC system to be designed around a liquid heat source which is more relevant for geothermal applications. The addition of a thermal extraction loop adds extra complexity to the cycle; an additional heat exchanger is required as well as an oil pump, which reduces the overall electrical output of the system. This is not necessary for future geothermal plants. The thermal oil selected from Petro-Canada is known as Calflo HTF. The oil was selected as it is readily available, operates at the required temperature range and has a reasonably low viscosity. A reduced viscosity is desirable as it minimizes the required pump work and increases the heat transfer. Figure 4 - Thermodynamic T-s diagram of conceptual design The duty of each component and proposed operating conditions are shown in Figure 5. Pevap = 695.8 [kPa] Tevap,sh = 80 [C] refrigerant$= r245fa Tdelta,superheat = 5 [C] Evaporator Tevap,sat = 75 [C] 20207 [W] Turbine Wexp = 1204 [W] Wgen = 1084 Vratio,exp = 3.432 [-] 56.03 [C] 211 [kPa] Condenser Tcond,sat = 35 [C] 19055 [W] Tdelta,subcool = 5 [C] Tcond,out = 30 [C] thermal = 0.05703 pump,isen=0.65 [-] m=0.09 [kg/s] Figure 5 - Steady state model of conceptual design 3.2.3 System Efficiency The system efficiency for an ORC system is a key performance parameter and is defined as: �� ��� ��� ��� ����� ��� ( 1) The thermal efficiency estimated for this design is 5.7%. The efficiency of an ORC system is typically very low due to the low resource temperatures which they utilize. The 35th New Zealand Geothermal Workshop: 2013 Proceedings 17 – 20 November 2013 Rotorua, New ZealandPDF Image | DESIGN AND BUILD OF A 1 KILOWATT ORGANIC RANKINE CYCLE POWER GENERATOR

PDF Search Title:

DESIGN AND BUILD OF A 1 KILOWATT ORGANIC RANKINE CYCLE POWER GENERATOROriginal File Name Searched:

Meyer_Final.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |