PDF Publication Title:

Text from PDF Page: 014

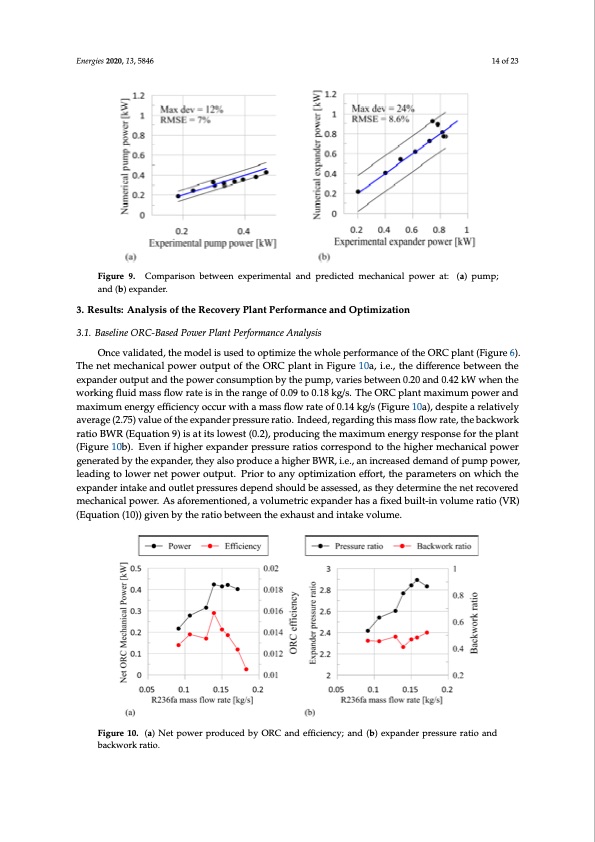

Figure 8. Comparison between the experimental and predicted (a) temperature at evaporator inlet; Energies 2020, 13, 5846 14 of 23 (b) temperature at expander inlet; (c) temperature at expander outlet; and (d) WF mass flow rate. Figure9.CoCmopmapriasroisnobnetbweetweneenxpexrpimereinmtaelnatanldapnrdedpicrtedicmteedchmaneichaalnpiocwalerpoatw:(ear)aptu:m(pa;)apnudm(bp); aenxdpa(nbd) erx.pander. 3. Results: Analysis of the Recovery Plant Performance and Optimization 3. Results: Analysis of the Recovery Plant Performance and Optimization 3.1. Baseline ORC-Based Power Plant Performance Analysis 3.1. Baseline ORC-Based Power Plant Performance Analysis Once validated, the model is used to optimize the whole performance of the ORC plant (Figure 6). Once validated, the model is used to optimize the whole performance of the ORC plant (Figure The net mechanical power output of the ORC plant in Figure 10a, i.e., the difference between the 6). The net mechanical power output of the ORC plant in Figure 10a, i.e., the difference between the expander output and the power consumption by the pump, varies between 0.20 and 0.42 kW when the Energies 2020, 13, x FOR PEER REVIEW 15 of 24 expander output and the power consumption by the pump, varies between 0.20 and 0.42 kW when working fluid mass flow rate is in the range of 0.09 to 0.18 kg/s. The ORC plant maximum power and the working fluid mass flow rate is in the range of 0.09 to 0.18 kg/s. The ORC plant maximum power maximum energy efficiency occur with a mass flow rate of 0.14 kg/s (Figure 10a), despite a relatively relatively average (2.75) value of the expander pressure ratio. Indeed, regarding this mass flow rate, and maximum energy efficiency occur with a mass flow rate of 0.14 kg/s (Figure 10a), despite a average (2.75) value of the expander pressure ratio. Indeed, regarding this mass flow rate, the backwork the backwork ratio BWR (Equation 9) is at its lowest (0.2), producing the maximum energy response ratio BWR (Equation 9) is at its lowest (0.2), producing the maximum energy response for the plant for the plant (Figure 10b). Even if higher expander pressure ratios correspond to the higher (Figure 10b). Even if higher expander pressure ratios correspond to the higher mechanical power mechanical power generated by the expander, they also produce a higher BWR, i.e., an increased generated by the expander, they also produce a higher BWR, i.e., an increased demand of pump power, demand of pump power, leading to lower net power output. Prior to any optimization effort, the leading to lower net power output. Prior to any optimization effort, the parameters on which the parameters on which the expander intake and outlet pressures depend should be assessed, as they expander intake and outlet pressures depend should be assessed, as they determine the net recovered determine the net recovered mechanical power. As aforementioned, a volumetric expander has a mechanical power. As aforementioned, a volumetric expander has a fixed built-in volume ratio (VR) fixed built-in volume ratio (VR) (Equation (10)) given by the ratio between the exhaust and intake (Equation (10)) given by the ratio between the exhaust and intake volume. volume. Figure 10. (a) Net power produced by ORC and efficiency; and (b) expander pressure ratio and Figure 10. (a) Net power produced by ORC and efficiency; and (b) expander pressure ratio and backwork ratio. backwork ratio. Experimental evidence suggests that for given intake conditions (i.e., pressure and temperature), the vane pressure at the exhaust port opening hardly matches the fluid one at the expander outlet. The experimental indicated cycle in Figure 11a shows an overexpansion with respect to the circuit pressure, pexh, which leads to an isochoric recompression of the working fluid at the exhaust start and eventually to a lower indicated mechanical power. Thus, the term overexpansion means that the pressure of the fluid at the exhaust port opening is lower than that imposed by the fluid. ThePDF Image | Design of ORC Plant for Low-Grade Waste Heat Recovery

PDF Search Title:

Design of ORC Plant for Low-Grade Waste Heat RecoveryOriginal File Name Searched:

energies-13-05846-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |