PDF Publication Title:

Text from PDF Page: 003

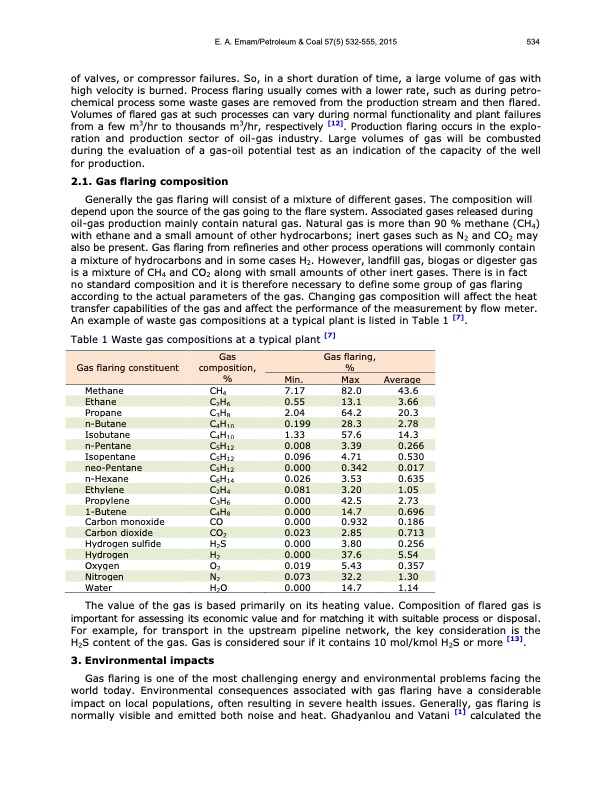

Methane Propane Isobutane Isopentane n-Hexane Propylene Carbon monoxide Hydrogen sulfide Oxygen Water CH4 7.17 82.0 43.6 C3H8 2.04 64.2 20.3 C4H10 1.33 57.6 14.3 C5H12 0.096 4.71 0.530 C6H14 0.026 3.53 0.635 C3H6 0.000 42.5 2.73 CO 0.000 0.932 0.186 H2S 0.000 3.80 0.256 O2 0.019 5.43 0.357 H2O 0.000 14.7 1.14 E. A. Emam/Petroleum & Coal 57(5) 532-555, 2015 534 of valves, or compressor failures. So, in a short duration of time, a large volume of gas with high velocity is burned. Process flaring usually comes with a lower rate, such as during petro- chemical process some waste gases are removed from the production stream and then flared. Volumes of flared gas at such processes can vary during normal functionality and plant failures from a few m3/hr to thousands m3/hr, respectively [12]. Production flaring occurs in the explo- ration and production sector of oil-gas industry. Large volumes of gas will be combusted during the evaluation of a gas-oil potential test as an indication of the capacity of the well for production. 2.1. Gas flaring composition Generally the gas flaring will consist of a mixture of different gases. The composition will depend upon the source of the gas going to the flare system. Associated gases released during oil-gas production mainly contain natural gas. Natural gas is more than 90 % methane (CH4) with ethane and a small amount of other hydrocarbons; inert gases such as N2 and CO2 may also be present. Gas flaring from refineries and other process operations will commonly contain a mixture of hydrocarbons and in some cases H2. However, landfill gas, biogas or digester gas is a mixture of CH4 and CO2 along with small amounts of other inert gases. There is in fact no standard composition and it is therefore necessary to define some group of gas flaring according to the actual parameters of the gas. Changing gas composition will affect the heat transfer capabilities of the gas and affect the performance of the measurement by flow meter. An example of waste gas compositions at a typical plant is listed in Table 1 [7]. Table 1 Waste gas compositions at a typical plant [7] Gas flaring constituent Gas composition, % Gas flaring, % Min. Max Average Ethane C2H6 0.55 13.1 3.66 n-Butane C4H10 0.199 28.3 2.78 n-Pentane C5H12 0.008 3.39 0.266 neo-Pentane C5H12 0.000 0.342 0.017 Ethylene C2H4 0.081 3.20 1.05 1-Butene C4H8 0.000 14.7 0.696 Carbon dioxide CO2 0.023 2.85 0.713 Hydrogen H2 0.000 37.6 5.54 Nitrogen N2 0.073 32.2 1.30 The value of the gas is based primarily on its heating value. Composition of flared gas is important for assessing its economic value and for matching it with suitable process or disposal. For example, for transport in the upstream pipeline network, the key consideration is the H2S content of the gas. Gas is considered sour if it contains 10 mol/kmol H2S or more [13]. 3. Environmental impacts Gas flaring is one of the most challenging energy and environmental problems facing the world today. Environmental consequences associated with gas flaring have a considerable impact on local populations, often resulting in severe health issues. Generally, gas flaring is normally visible and emitted both noise and heat. Ghadyanlou and Vatani [1] calculated thePDF Image | GAS FLARING IN INDUSTRY

PDF Search Title:

GAS FLARING IN INDUSTRYOriginal File Name Searched:

emam.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |