PDF Publication Title:

Text from PDF Page: 002

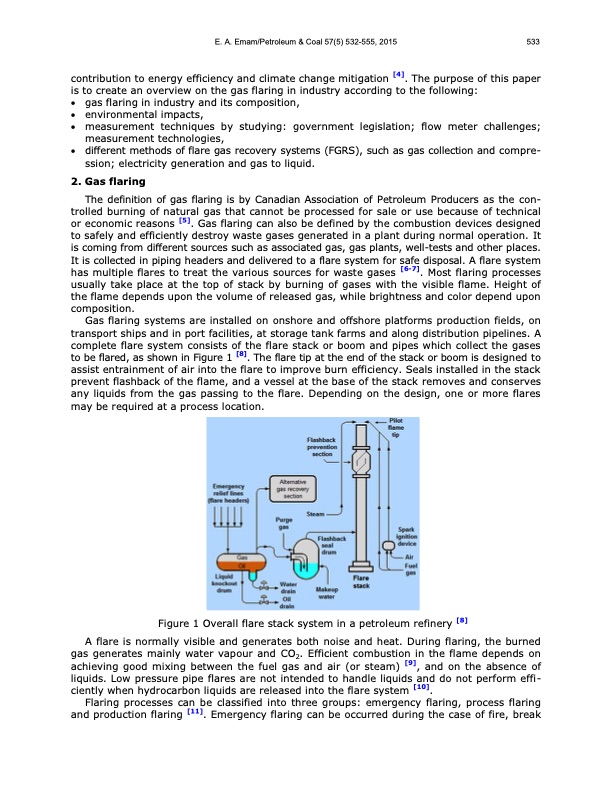

E. A. Emam/Petroleum & Coal 57(5) 532-555, 2015 533 contribution to energy efficiency and climate change mitigation [4]. The purpose of this paper is to create an overview on the gas flaring in industry according to the following: gas flaring in industry and its composition, environmental impacts, measurement techniques by studying: government legislation; flow meter challenges; measurement technologies, different methods of flare gas recovery systems (FGRS), such as gas collection and compre- ssion; electricity generation and gas to liquid. 2. Gas flaring The definition of gas flaring is by Canadian Association of Petroleum Producers as the con- trolled burning of natural gas that cannot be processed for sale or use because of technical or economic reasons [5]. Gas flaring can also be defined by the combustion devices designed to safely and efficiently destroy waste gases generated in a plant during normal operation. It is coming from different sources such as associated gas, gas plants, well-tests and other places. It is collected in piping headers and delivered to a flare system for safe disposal. A flare system has multiple flares to treat the various sources for waste gases [6-7]. Most flaring processes usually take place at the top of stack by burning of gases with the visible flame. Height of the flame depends upon the volume of released gas, while brightness and color depend upon composition. Gas flaring systems are installed on onshore and offshore platforms production fields, on transport ships and in port facilities, at storage tank farms and along distribution pipelines. A complete flare system consists of the flare stack or boom and pipes which collect the gases to be flared, as shown in Figure 1 [8]. The flare tip at the end of the stack or boom is designed to assist entrainment of air into the flare to improve burn efficiency. Seals installed in the stack prevent flashback of the flame, and a vessel at the base of the stack removes and conserves any liquids from the gas passing to the flare. Depending on the design, one or more flares may be required at a process location. Figure 1 Overall flare stack system in a petroleum refinery [8] A flare is normally visible and generates both noise and heat. During flaring, the burned gas generates mainly water vapour and CO2. Efficient combustion in the flame depends on achieving good mixing between the fuel gas and air (or steam) [9], and on the absence of liquids. Low pressure pipe flares are not intended to handle liquids and do not perform effi- ciently when hydrocarbon liquids are released into the flare system [10]. Flaring processes can be classified into three groups: emergency flaring, process flaring and production flaring [11]. Emergency flaring can be occurred during the case of fire, breakPDF Image | GAS FLARING IN INDUSTRY

PDF Search Title:

GAS FLARING IN INDUSTRYOriginal File Name Searched:

emam.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |