PDF Publication Title:

Text from PDF Page: 013

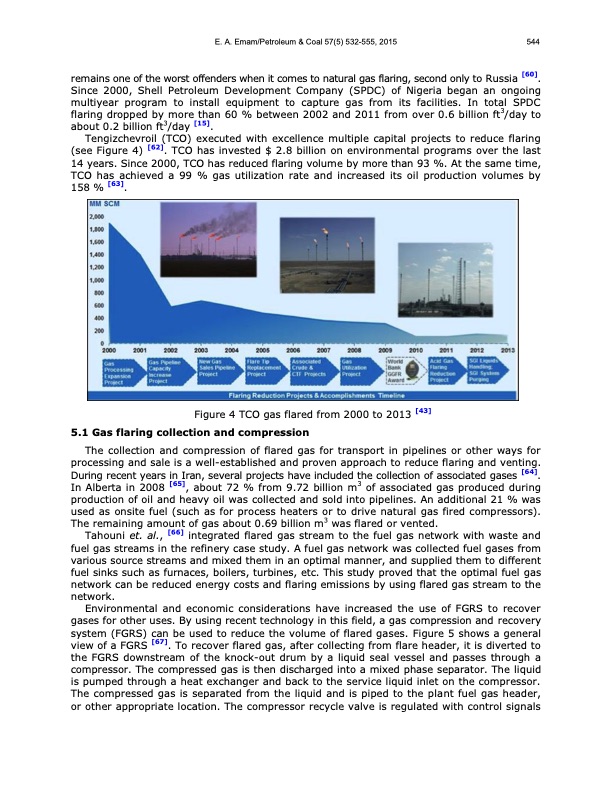

E. A. Emam/Petroleum & Coal 57(5) 532-555, 2015 544 remains one of the worst offenders when it comes to natural gas flaring, second only to Russia [60]. Since 2000, Shell Petroleum Development Company (SPDC) of Nigeria began an ongoing multiyear program to install equipment to capture gas from its facilities. In total SPDC flaring dropped by more than 60 % between 2002 and 2011 from over 0.6 billion ft3/day to about 0.2 billion ft3/day [15]. Tengizchevroil (TCO) executed with excellence multiple capital projects to reduce flaring (see Figure 4) [62]. TCO has invested $ 2.8 billion on environmental programs over the last 14 years. Since 2000, TCO has reduced flaring volume by more than 93 %. At the same time, TCO has achieved a 99 % gas utilization rate and increased its oil production volumes by 158 % [63]. Figure 4 TCO gas flared from 2000 to 2013 [43] 5.1 Gas flaring collection and compression The collection and compression of flared gas for transport in pipelines or other ways for processing and sale is a well-established and proven approach to reduce flaring and venting. During recent years in Iran, several projects have included the collection of associated gases [64]. In Alberta in 2008 [65], about 72 % from 9.72 billion m3 of associated gas produced during production of oil and heavy oil was collected and sold into pipelines. An additional 21 % was used as onsite fuel (such as for process heaters or to drive natural gas fired compressors). The remaining amount of gas about 0.69 billion m3 was flared or vented. Tahouni et. al., [66] integrated flared gas stream to the fuel gas network with waste and fuel gas streams in the refinery case study. A fuel gas network was collected fuel gases from various source streams and mixed them in an optimal manner, and supplied them to different fuel sinks such as furnaces, boilers, turbines, etc. This study proved that the optimal fuel gas network can be reduced energy costs and flaring emissions by using flared gas stream to the network. Environmental and economic considerations have increased the use of FGRS to recover gases for other uses. By using recent technology in this field, a gas compression and recovery system (FGRS) can be used to reduce the volume of flared gases. Figure 5 shows a general view of a FGRS [67]. To recover flared gas, after collecting from flare header, it is diverted to the FGRS downstream of the knock-out drum by a liquid seal vessel and passes through a compressor. The compressed gas is then discharged into a mixed phase separator. The liquid is pumped through a heat exchanger and back to the service liquid inlet on the compressor. The compressed gas is separated from the liquid and is piped to the plant fuel gas header, or other appropriate location. The compressor recycle valve is regulated with control signalsPDF Image | GAS FLARING IN INDUSTRY

PDF Search Title:

GAS FLARING IN INDUSTRYOriginal File Name Searched:

emam.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |