PDF Publication Title:

Text from PDF Page: 014

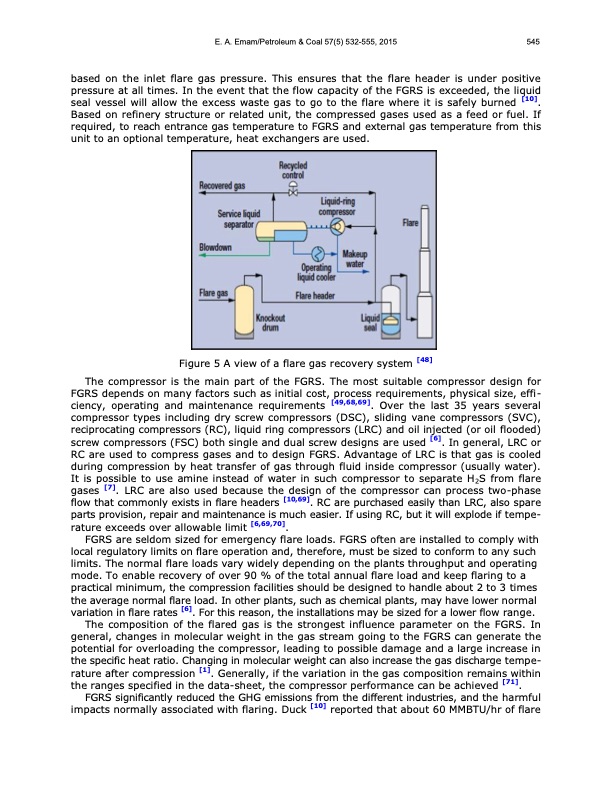

E. A. Emam/Petroleum & Coal 57(5) 532-555, 2015 545 based on the inlet flare gas pressure. This ensures that the flare header is under positive pressure at all times. In the event that the flow capacity of the FGRS is exceeded, the liquid seal vessel will allow the excess waste gas to go to the flare where it is safely burned [10]. Based on refinery structure or related unit, the compressed gases used as a feed or fuel. If required, to reach entrance gas temperature to FGRS and external gas temperature from this unit to an optional temperature, heat exchangers are used. Figure 5 A view of a flare gas recovery system [48] The compressor is the main part of the FGRS. The most suitable compressor design for FGRS depends on many factors such as initial cost, process requirements, physical size, effi- ciency, operating and maintenance requirements [49,68,69]. Over the last 35 years several compressor types including dry screw compressors (DSC), sliding vane compressors (SVC), reciprocating compressors (RC), liquid ring compressors (LRC) and oil injected (or oil flooded) screw compressors (FSC) both single and dual screw designs are used [6]. In general, LRC or RC are used to compress gases and to design FGRS. Advantage of LRC is that gas is cooled during compression by heat transfer of gas through fluid inside compressor (usually water). It is possible to use amine instead of water in such compressor to separate H2S from flare gases [7]. LRC are also used because the design of the compressor can process two-phase flow that commonly exists in flare headers [10,69]. RC are purchased easily than LRC, also spare parts provision, repair and maintenance is much easier. If using RC, but it will explode if tempe- rature exceeds over allowable limit [6,69,70]. FGRS are seldom sized for emergency flare loads. FGRS often are installed to comply with local regulatory limits on flare operation and, therefore, must be sized to conform to any such limits. The normal flare loads vary widely depending on the plants throughput and operating mode. To enable recovery of over 90 % of the total annual flare load and keep flaring to a practical minimum, the compression facilities should be designed to handle about 2 to 3 times the average normal flare load. In other plants, such as chemical plants, may have lower normal variation in flare rates [6]. For this reason, the installations may be sized for a lower flow range. The composition of the flared gas is the strongest influence parameter on the FGRS. In general, changes in molecular weight in the gas stream going to the FGRS can generate the potential for overloading the compressor, leading to possible damage and a large increase in the specific heat ratio. Changing in molecular weight can also increase the gas discharge tempe- rature after compression [1]. Generally, if the variation in the gas composition remains within the ranges specified in the data-sheet, the compressor performance can be achieved [71]. FGRS significantly reduced the GHG emissions from the different industries, and the harmful impacts normally associated with flaring. Duck [10] reported that about 60 MMBTU/hr of flarePDF Image | GAS FLARING IN INDUSTRY

PDF Search Title:

GAS FLARING IN INDUSTRYOriginal File Name Searched:

emam.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |