PDF Publication Title:

Text from PDF Page: 019

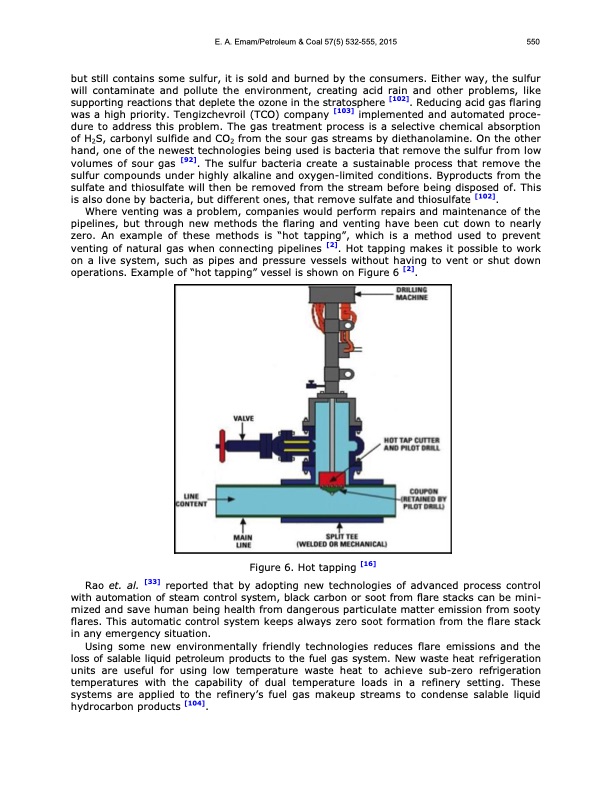

E. A. Emam/Petroleum & Coal 57(5) 532-555, 2015 550 but still contains some sulfur, it is sold and burned by the consumers. Either way, the sulfur will contaminate and pollute the environment, creating acid rain and other problems, like supporting reactions that deplete the ozone in the stratosphere [102]. Reducing acid gas flaring was a high priority. Tengizchevroil (TCO) company [103] implemented and automated proce- dure to address this problem. The gas treatment process is a selective chemical absorption of H2S, carbonyl sulfide and CO2 from the sour gas streams by diethanolamine. On the other hand, one of the newest technologies being used is bacteria that remove the sulfur from low volumes of sour gas [92]. The sulfur bacteria create a sustainable process that remove the sulfur compounds under highly alkaline and oxygen-limited conditions. Byproducts from the sulfate and thiosulfate will then be removed from the stream before being disposed of. This is also done by bacteria, but different ones, that remove sulfate and thiosulfate [102]. Where venting was a problem, companies would perform repairs and maintenance of the pipelines, but through new methods the flaring and venting have been cut down to nearly zero. An example of these methods is “hot tapping”, which is a method used to prevent venting of natural gas when connecting pipelines [2]. Hot tapping makes it possible to work on a live system, such as pipes and pressure vessels without having to vent or shut down operations. Example of “hot tapping” vessel is shown on Figure 6 [2]. Figure 6. Hot tapping [16] Rao et. al. [33] reported that by adopting new technologies of advanced process control with automation of steam control system, black carbon or soot from flare stacks can be mini- mized and save human being health from dangerous particulate matter emission from sooty flares. This automatic control system keeps always zero soot formation from the flare stack in any emergency situation. Using some new environmentally friendly technologies reduces flare emissions and the loss of salable liquid petroleum products to the fuel gas system. New waste heat refrigeration units are useful for using low temperature waste heat to achieve sub-zero refrigeration temperatures with the capability of dual temperature loads in a refinery setting. These systems are applied to the refinery’s fuel gas makeup streams to condense salable liquid hydrocarbon products [104].PDF Image | GAS FLARING IN INDUSTRY

PDF Search Title:

GAS FLARING IN INDUSTRYOriginal File Name Searched:

emam.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |