PDF Publication Title:

Text from PDF Page: 040

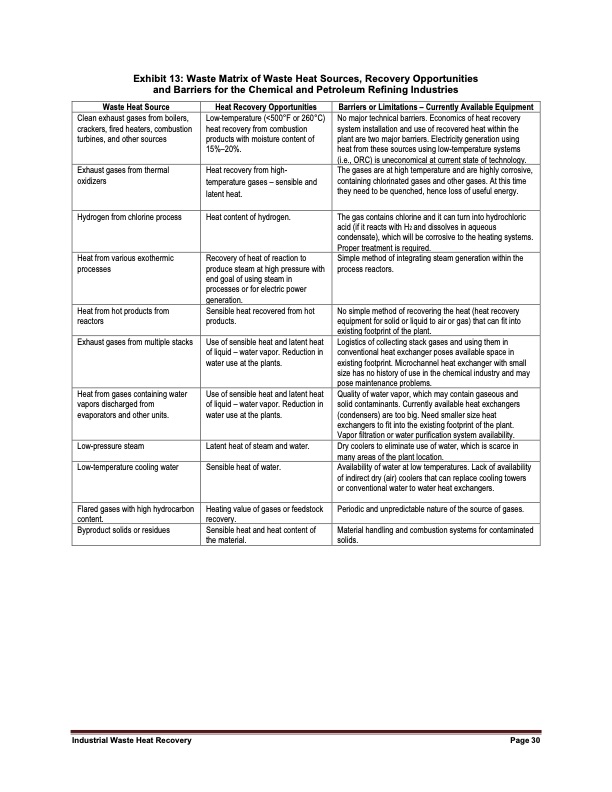

Exhibit 13: Waste Matrix of Waste Heat Sources, Recovery Opportunities and Barriers for the Chemical and Petroleum Refining Industries Waste Heat Source Heat Recovery Opportunities Barriers or Limitations – Currently Available Equipment Clean exhaust gases from boilers, crackers, fired heaters, combustion turbines, and other sources Low-temperature (<500°F or 260°C) heat recovery from combustion products with moisture content of 15%–20%. No major technical barriers. Economics of heat recovery system installation and use of recovered heat within the plant are two major barriers. Electricity generation using heat from these sources using low-temperature systems (i.e., ORC) is uneconomical at current state of technology. Exhaust gases from thermal oxidizers Heat recovery from high- temperature gases – sensible and latent heat. The gases are at high temperature and are highly corrosive, containing chlorinated gases and other gases. At this time they need to be quenched, hence loss of useful energy. Hydrogen from chlorine process Heat content of hydrogen. The gas contains chlorine and it can turn into hydrochloric acid (if it reacts with H2 and dissolves in aqueous condensate), which will be corrosive to the heating systems. Proper treatment is required. Heat from various exothermic processes Recovery of heat of reaction to produce steam at high pressure with end goal of using steam in processes or for electric power generation. Simple method of integrating steam generation within the process reactors. Heat from hot products from reactors Low-pressure steam Flared gases with high hydrocarbon content. Byproduct solids or residues Sensible heat recovered from hot products. Latent heat of steam and water. Heating value of gases or feedstock recovery. Sensible heat and heat content of the material. No simple method of recovering the heat (heat recovery equipment for solid or liquid to air or gas) that can fit into existing footprint of the plant. Dry coolers to eliminate use of water, which is scarce in many areas of the plant location. Periodic and unpredictable nature of the source of gases. Material handling and combustion systems for contaminated solids. Exhaust gases from multiple stacks Use of sensible heat and latent heat of liquid – water vapor. Reduction in water use at the plants. Logistics of collecting stack gases and using them in conventional heat exchanger poses available space in existing footprint. Microchannel heat exchanger with small size has no history of use in the chemical industry and may pose maintenance problems. Heat from gases containing water vapors discharged from evaporators and other units. Use of sensible heat and latent heat of liquid – water vapor. Reduction in water use at the plants. Quality of water vapor, which may contain gaseous and solid contaminants. Currently available heat exchangers (condensers) are too big. Need smaller size heat exchangers to fit into the existing footprint of the plant. Vapor filtration or water purification system availability. Low-temperature cooling water Sensible heat of water. Availability of water at low temperatures. Lack of availability of indirect dry (air) coolers that can replace cooling towers or conventional water to water heat exchangers. Industrial Waste Heat Recovery Page 30PDF Image | Industrial Waste Heat Recovery: Potential

PDF Search Title:

Industrial Waste Heat Recovery: PotentialOriginal File Name Searched:

Pub52987.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |