PDF Publication Title:

Text from PDF Page: 067

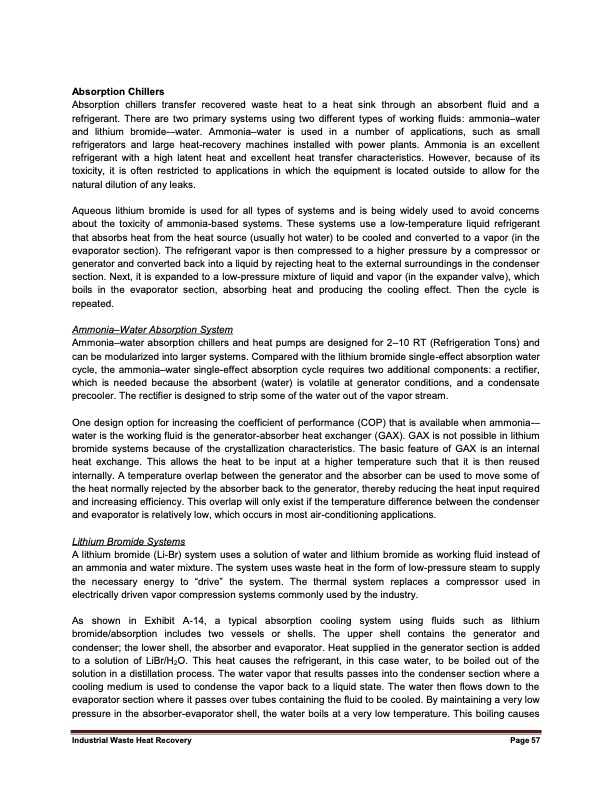

Absorption Chillers Absorption chillers transfer recovered waste heat to a heat sink through an absorbent fluid and a refrigerant. There are two primary systems using two different types of working fluids: ammonia–water and lithium bromide-–water. Ammonia–water is used in a number of applications, such as small refrigerators and large heat-recovery machines installed with power plants. Ammonia is an excellent refrigerant with a high latent heat and excellent heat transfer characteristics. However, because of its toxicity, it is often restricted to applications in which the equipment is located outside to allow for the natural dilution of any leaks. Aqueous lithium bromide is used for all types of systems and is being widely used to avoid concerns about the toxicity of ammonia-based systems. These systems use a low-temperature liquid refrigerant that absorbs heat from the heat source (usually hot water) to be cooled and converted to a vapor (in the evaporator section). The refrigerant vapor is then compressed to a higher pressure by a compressor or generator and converted back into a liquid by rejecting heat to the external surroundings in the condenser section. Next, it is expanded to a low-pressure mixture of liquid and vapor (in the expander valve), which boils in the evaporator section, absorbing heat and producing the cooling effect. Then the cycle is repeated. Ammonia–Water Absorption System Ammonia–water absorption chillers and heat pumps are designed for 2–10 RT (Refrigeration Tons) and can be modularized into larger systems. Compared with the lithium bromide single-effect absorption water cycle, the ammonia–water single-effect absorption cycle requires two additional components: a rectifier, which is needed because the absorbent (water) is volatile at generator conditions, and a condensate precooler. The rectifier is designed to strip some of the water out of the vapor stream. One design option for increasing the coefficient of performance (COP) that is available when ammonia-– water is the working fluid is the generator-absorber heat exchanger (GAX). GAX is not possible in lithium bromide systems because of the crystallization characteristics. The basic feature of GAX is an internal heat exchange. This allows the heat to be input at a higher temperature such that it is then reused internally. A temperature overlap between the generator and the absorber can be used to move some of the heat normally rejected by the absorber back to the generator, thereby reducing the heat input required and increasing efficiency. This overlap will only exist if the temperature difference between the condenser and evaporator is relatively low, which occurs in most air-conditioning applications. Lithium Bromide Systems A lithium bromide (Li-Br) system uses a solution of water and lithium bromide as working fluid instead of an ammonia and water mixture. The system uses waste heat in the form of low-pressure steam to supply the necessary energy to “drive” the system. The thermal system replaces a compressor used in electrically driven vapor compression systems commonly used by the industry. As shown in Exhibit A-14, a typical absorption cooling system using fluids such as lithium bromide/absorption includes two vessels or shells. The upper shell contains the generator and condenser; the lower shell, the absorber and evaporator. Heat supplied in the generator section is added to a solution of LiBr/H2O. This heat causes the refrigerant, in this case water, to be boiled out of the solution in a distillation process. The water vapor that results passes into the condenser section where a cooling medium is used to condense the vapor back to a liquid state. The water then flows down to the evaporator section where it passes over tubes containing the fluid to be cooled. By maintaining a very low pressure in the absorber-evaporator shell, the water boils at a very low temperature. This boiling causes Industrial Waste Heat Recovery Page 57PDF Image | Industrial Waste Heat Recovery: Potential

PDF Search Title:

Industrial Waste Heat Recovery: PotentialOriginal File Name Searched:

Pub52987.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |