PDF Publication Title:

Text from PDF Page: 007

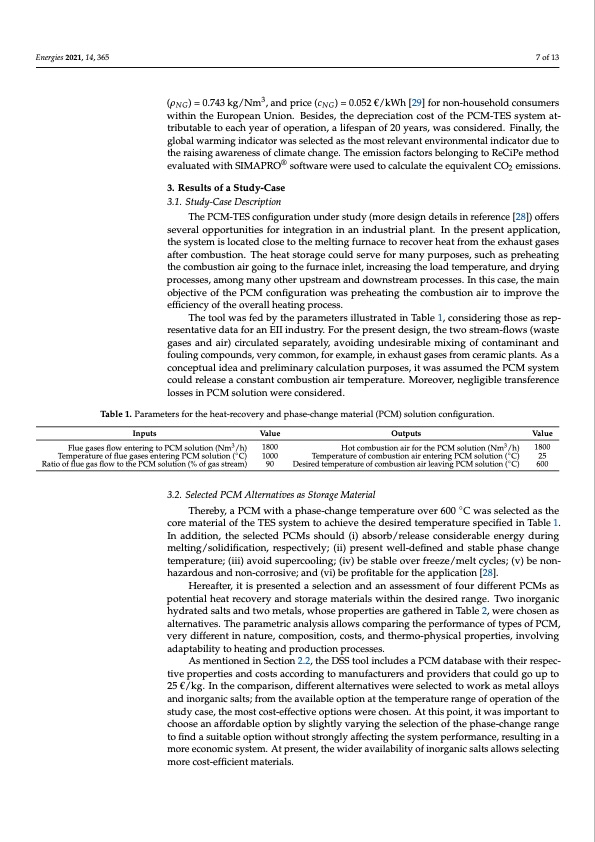

Energies 2021, 14, 365 7 of 13 Inputs Value Flue gases flow entering to PCM solution (Nm3/h) 1800 Temperature of flue gases entering PCM solution (◦C) 1000 Ratio of flue gas flow to the PCM solution (% of gas stream) 90 Outputs Value (ρNG) = 0.743 kg/Nm3, and price (cNG) = 0.052 €/kWh [29] for non-household consumers within the European Union. Besides, the depreciation cost of the PCM-TES system at- tributable to each year of operation, a lifespan of 20 years, was considered. Finally, the global warming indicator was selected as the most relevant environmental indicator due to the raising awareness of climate change. The emission factors belonging to ReCiPe method evaluated with SIMAPRO® software were used to calculate the equivalent CO2 emissions. 3. Results of a Study-Case 3.1. Study-Case Description The PCM-TES configuration under study (more design details in reference [28]) offers several opportunities for integration in an industrial plant. In the present application, the system is located close to the melting furnace to recover heat from the exhaust gases after combustion. The heat storage could serve for many purposes, such as preheating the combustion air going to the furnace inlet, increasing the load temperature, and drying processes, among many other upstream and downstream processes. In this case, the main objective of the PCM configuration was preheating the combustion air to improve the efficiency of the overall heating process. The tool was fed by the parameters illustrated in Table 1, considering those as rep- resentative data for an EII industry. For the present design, the two stream-flows (waste gases and air) circulated separately, avoiding undesirable mixing of contaminant and fouling compounds, very common, for example, in exhaust gases from ceramic plants. As a conceptual idea and preliminary calculation purposes, it was assumed the PCM system could release a constant combustion air temperature. Moreover, negligible transference losses in PCM solution were considered. Table 1. Parameters for the heat-recovery and phase-change material (PCM) solution configuration. Hot combustion air for the PCM solution (Nm3/h) 1800 Temperature of combustion air entering PCM solution (◦C) 25 Desired temperature of combustion air leaving PCM solution (◦C) 600 3.2. Selected PCM Alternatives as Storage Material Thereby, a PCM with a phase-change temperature over 600 ◦C was selected as the core material of the TES system to achieve the desired temperature specified in Table 1. In addition, the selected PCMs should (i) absorb/release considerable energy during melting/solidification, respectively; (ii) present well-defined and stable phase change temperature; (iii) avoid supercooling; (iv) be stable over freeze/melt cycles; (v) be non- hazardous and non-corrosive; and (vi) be profitable for the application [28]. Hereafter, it is presented a selection and an assessment of four different PCMs as potential heat recovery and storage materials within the desired range. Two inorganic hydrated salts and two metals, whose properties are gathered in Table 2, were chosen as alternatives. The parametric analysis allows comparing the performance of types of PCM, very different in nature, composition, costs, and thermo-physical properties, involving adaptability to heating and production processes. As mentioned in Section 2.2, the DSS tool includes a PCM database with their respec- tive properties and costs according to manufacturers and providers that could go up to 25 €/kg. In the comparison, different alternatives were selected to work as metal alloys and inorganic salts; from the available option at the temperature range of operation of the study case, the most cost-effective options were chosen. At this point, it was important to choose an affordable option by slightly varying the selection of the phase-change range to find a suitable option without strongly affecting the system performance, resulting in a more economic system. At present, the wider availability of inorganic salts allows selecting more cost-efficient materials.PDF Image | Latent Heat Storage for Waste Heat Recovery in the Energy Industry

PDF Search Title:

Latent Heat Storage for Waste Heat Recovery in the Energy IndustryOriginal File Name Searched:

energies-14-00365-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |